Case Studies / Press releases · January 18th 2020

European nuclear physics laboratory relies on

digital procurement of parts for neutron shields

FACTUREE produces radiation protection components for the European research center CERN

Berlin, 18th January 2021 – CERN, the European Organization for Nuclear Research, is one of the world’s largest and most renowned centers for basic physics research. The CMS experiment conducted by CERN is considered one of the largest international scientific collaborations in history. For this experiment, CERN entrusted FACTUREE – The Online Manufacturer (www.facturee.de) with procuring special parts for the complex CMS particle detector developed specifically for this purpose. In an extensive project, FACTUREE produced steel pipes and plates used in the physics experiment as components for neutron shields.

At CERN (Conseil Européen pour la Recherche Nucléaire) in Geneva, scientists explore the fundamental laws of the universe. The European project was founded in 1954 and has 23 member states, including the United Kingdom and Germany as a founding members. CERN employs more than 12,000 scientists from 85 countries.

Needed quickly: high-quality special protective shield for particle detector

The European nuclear physics laboratory provides its researchers a unique array of particle accelerators. At CERN, the world’s largest and most complex machines are used to research the smallest units of matter – elementary particles.

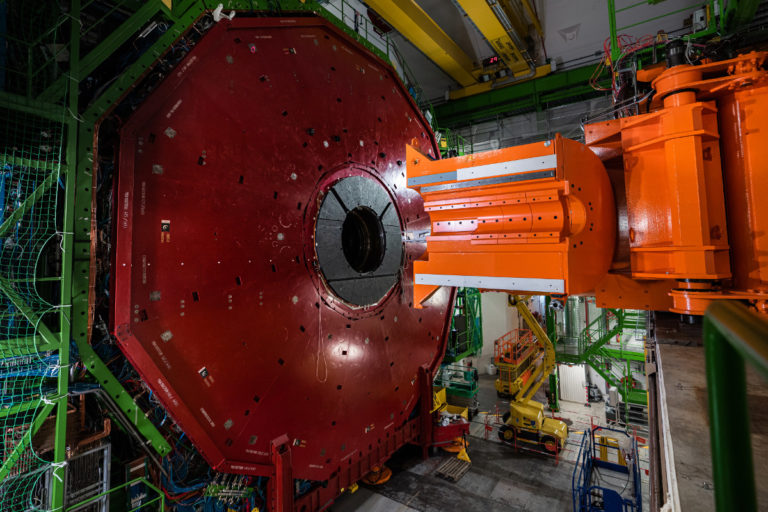

The Compact Muon Solenoid (CMS) experiment is a particle detector at the Large Hadron Collider (LHC) at CERN in Switzerland. An underground hall in the accelerator ring near Cessy in France hosts the large-scale experiment involving – as of September 2019 – 5000 particle physicists, engineers, technicians, students and assistants from 200 institutes in 50 countries.

Ali Karaki, Mechanical Engineer at CMS/CERN, states: “For this important experiment, we needed a special protective shield, as our previous shields were contaminated with radiation. When searching for a manufacturer, the key factors were procurement time, quality and handling. There are currently only a few companies in Europe that can manufacture large-scale parts precisely and reliably. We have already had positive experiences with FACTUREE in procuring precision parts, sample holders, adapter pieces, etc. and we therefore opted for the online manufacturer for this project as well.”

When awarding the contract for this major project, knowledge of the exact chemical composition of the steel used was also decisive. Lukas Schlicker, Head of Purchasing at cwmk GmbH, explains: “In order to calculate the effectiveness of the protective shields against radiation, you must know the exact chemical composition of the steel batch. We were able to give CERN the chemical analysis of the batch intended for use in production during the quotation phase. The effectiveness of the protective shields was then simulated and confirmed at CERN.

cwmk GmbH operates as an Online Manufacturer under the FACTUREE brand name. FACTUREE has a broad network of over 1000 production partners across the areas of CNC machining, sheet metal processing, 3D printing, and surface technology. More than 8000 machines are always at the ready for projects, ensuring on-time deliveries. The company has an ISO 9001 certified quality management system.

Fast procurement and cost advantages

FACTUREE produced a total of 5 metric tons of steel pipes and plates for CERN that were used in the CMS experiment as components for radiation protection. The contract also included special features and services, among them the procurement of raw material, processing, painting, assembly and delivery.

Ali Karaki sums up: “The quotation from FACTUREE was fast, as was delivery of the components. We found no defects in the incoming inspection. The costs for the components were around 15% lower than from other providers in Europe. If CERN should ever need components for protective shields such as steel plates or pipes in the future, we will definitely turn to FACTUREE for procurement again.”

Profile of FACTUREE – The Online Manufacturer:

cwmk GmbH, based in Berlin, operates under the brand name FACTUREE as the first Online Manufacturer. The company pursues the goal of enabling its customers to procure modern production parts through digitization, automation and networking. FACTUREE has an extensive production network of over 1000 manufacturing partners from the fields of CNC machining, sheet metal production, 3D printing and surface technology. More than 8000 machines are constantly available for projects. All partners are subject to a continuous data-driven quality management system certified according to ISO 9001. FACTUREE can realize prototyping projects as well as small and large series production. The customer base is located in the most diverse fields such as mechanical engineering, medical technology, model making, robotics, automotive as well as aerospace. Leading industrial companies like Siemens and Parker Hannifin, SMEs, research institutes and universities are among the customers. FACTUREE is active throughout Europe and has a continuously growing number of customers in other European countries.

Further information: www.facturee.de