Press releases · 13. May 2022

3D printing can lead to more flexibility and independence from global supply chains

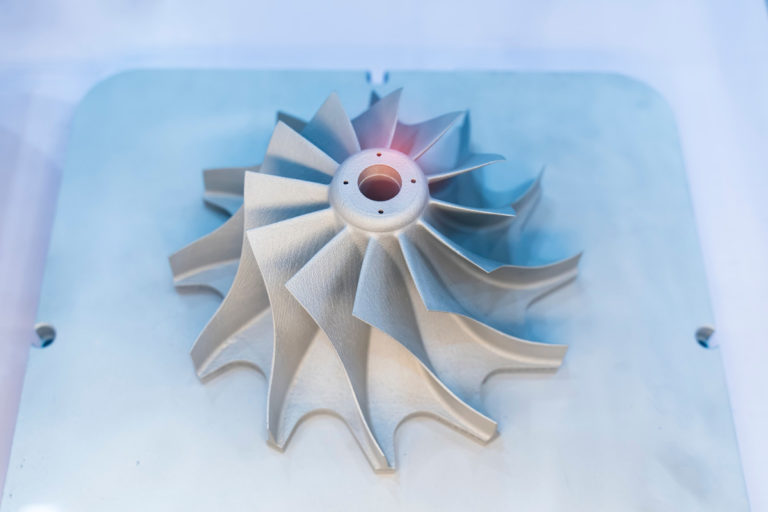

FACTUREE reviews the role of additive manufacturing in re-regionalization

Berlin, 16 May 2022 – The re-regionalization of supply chains is gaining significance in the procurement crisis and can be supported by additive manufacturing. Due to a high level of automation and a relatively low ratio of labor to production costs, even industrialized, high-wage countries in the EU could manufacture more competitively and become more independent on an international level. This is the view of the Online Manufacturer FACTUREE (www.facturee.de) which has an extensive network of some 2,000 manufacturing partners from nearly all areas – currently the company is expanding its range in 3D metal printing, where it sees great potential for the industry, but also limitations.

Supply issues, long distances and material bottlenecks often lead to production delays. Additive manufacturing can counteract this difficulty, as parts can be manufactured locally on demand. Components made by additive manufacturing can thus help avoid supply bottlenecks. Just-in-time production also leads to savings, for example in storage costs, as parts can be manufactured using 3D printing when and where they are needed, eliminating the need to stockpile spare parts, for instance.

“There are high hopes for additive manufacturing with respect to re-regionalization of manufacturing. However, it is not realistic to think we will quickly become independent. There are still too many economic dependencies. Furthermore, additive manufacturing has many technological restrictions that limit its use in industry. One large obstacle is the confusing number of materials and proprietary manufacturing processes, sometimes posing huge challenges for engineers and creating uncertainty. I see a great need for action regarding harmonization and standardization and I am hoping for the consolidation of the market. Nevertheless, the technology has made impressive progress and will continue to build its position,” explains Benjamin Schwab, co-founder and CMO of FACTUREE.

Online Manufacturing with a technology-agnostic approach

FACTUREE is making additive manufacturing and its advantages available to companies. The Online Manufacturer has access to a large manufacturing network of some 2,000 partners in nearly all areas – including CNC machining, sheet metal processing, 3D printing and surface technology. The area of 3D metal printing is currently being expanded.

“When prospective clients ask us for components that were designed as CNC parts but could be made at a lower cost using 3D printing, we point out this option, which is frequently their first contact with additive manufacturing. This is how we promote acceptance. However, the technology is not a one-size-fits-all solution – the right process always has to be found on a case-by-case basis,” says Benjamin Schwab.

FACTUREE selects the most suitable manufacturer for each requirement and recommends the appropriate manufacturing process. “Especially when specific requirements for mechanical properties, tolerances and surface quality have to be met, additive manufacturing is not an alternative to established manufacturing processes such as CNC machining in the industrial setting. The great advantage of our eco¬system is that we are not tied to one manufacturing method but are free to choose the one that best meets the need,” explains Benjamin Schwab.

Characters: 3,475

Profile of FACTUREE – The Online Manufacturer:

cwmk GmbH, based in Berlin, operates under the brand name FACTUREE as the first Online Manufacturer. The company pursues the goal of enabling its customers to procure modern production parts through digitization, automation and networking. FACTUREE has an extensive production network of over 1000 manufacturing partners from the fields of CNC machining, sheet metal production, 3D printing and surface technology. More than 15000 machines are constantly available for projects. All partners are subject to a continuous data-driven quality management system certified according to ISO 9001. FACTUREE can realize prototyping projects as well as small and large series production. The customer base is located in the most diverse fields such as mechanical engineering, medical technology, model making, robotics, automotive as well as aerospace. Leading industrial companies like Siemens and Parker Hannifin, SMEs, research institutes and universities are among the customers. FACTUREE is active throughout Europe and has a continuously growing number of customers in other European countries.

Further information: www.facturee.de