Large network + smart selection = Online Manufacturing

As the Online Manufacturer with a network of more than 2000 manufacturing partners, FACTUREE has access to nearly unlimited capacities for manufacturing laser parts, thus making your supply chains secure.

By using machine learning based algorithms we can find the best supplier in terms of quality, price and delivery time for all your laser cutting projects, from prototype to series production.

FACTUREE is your only contact and contract partner throughout the entire project and assumes full responsibility for on-time delivery and the quality of your laser cut parts.

How Online Manufacturing of laser parts works at FACTUREE

Inquiry

- Online request (.stp/.step preferred)

- Inquiries also possible by email

- Telephone customer service

Quoting process

- Express quotes – often on the same day

- Two-stage technical feasibility check

- Flexible offer optimization regarding price or delivery time

Order placement

- More than 2000 specialized manufacturing partners

- AI-supported selection of the optimal manufacturer

- FACTUREE is the sole contractual and contact partner

Manufacturing

- Broadest manufacturing range in the market

- Unlimited production capacity

- ISO 9001 certified quality management

Shipment

- Consistently short delivery times

- Europe-wide express shipping

- 100% climate neutral

Advantages over conventional procurement of laser parts

Find out more about the advantages of Online Manufacturing and how you can benefit from it in our latest white paper „The future of parts procurement“

From industry to top international research – more than 15,000 satisfied customers

Laser cutting at FACTUREE

Service range:

- Plate laser cutting + tube laser cutting

- Largest selection of materials on the market (incl. plastics)

- Incl. surface treatments

- Prototyping and large scale mass production

Specifications for laser parts:

- Max. dimensions: L: 6000 mm x W: 2000 mm

- Sheet thickness: from 0.5 mm

- Tolerances: from ±0.1 mm

- File formats: .stp/.step (preferred), .dxf, .pdf (optional)

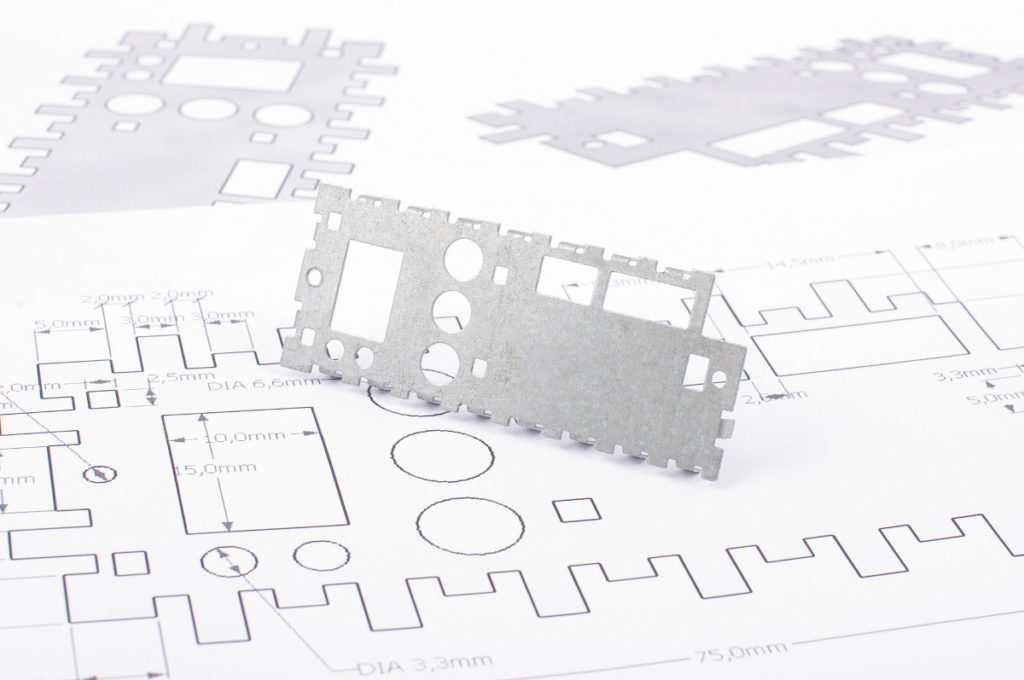

What is CNC laser cutting?

CNC laser cutting is a modern manufacturing technology that uses a computer-guided laser to precisely cut materials such as steel, aluminum, other metals and plastics. This method is known for its high accuracy and precision, making it ideal for manufacturing parts with complex shapes or tight tolerances.

CNC laser cutting generally uses plates, less often tubes, as semi-finished products that already have the desired size and shape. The laser then cuts precise patterns and shapes from the plate, resulting in the final part. With a high degree of efficiency, this method allows excellent accuracy and precision.

Laser cutting of plates

Laser cutting of plates is a key process in modern manufacturing technology. Using highly focused laser beams, plates of various kinds – steel, aluminum, other metals and also some thermoplastic materials – can be processed with a high level of precision. Thanks to its minimal thermal effects, the method lowers the risk of deformation. The cut edges are usually clean, reducing the need for reworking. This efficient cutting method is particularly requested in the automotive and mechanical engineering industries.

Selection of materials for laser parts

Benefit from our network with the largest selection of materials on the market. There is hardly any semi-finished product that cannot be quickly procured for your plate parts. And if it does happen, we can almost always find a suitable alternative.

Frequently requested materials

- EN AW-5083 | 3.3547 | AlMg4,5Mn

- EN AW-5754 | 3.3535 | AlMg3

- EN AW-6060 | 3.3206 | AlMgSi0,5

- EN AW-7075 | 3.4365 | AlZnMgCu1,5

- 1.0037 | S235JRC+C | St37k

- 1.0503 | C45

- 1.4301 | V2A

- 1.7225 | 42CrMo4

- Copper: ETP-Cu | 2.0060

- Brass: CW508L | CuZn37 | 2.0321

- PMMA (Acrylic glass)

- HDPE

- POM

Range of applications for laser cut parts

Laser parts are used in a number of industries, where they are valued as a precise, efficient and reasonably priced solution for manufacturing parts.

Laser parts offer huge advantages, especially in the aviation and aerospace industry, where weight and precision are critical factors. Automobile manufacturers rely on laser cutting to make precise parts in mass production, while medical technology benefits from the ability to produce extremely detailed components for instruments and devices. In electronics, laser parts enable the production of small, efficient components. Additionally, laser cutting is becoming ever more popular in art and architecture for creating custom designs and structures. The wide range of applications and versatility of laser cutting makes it an indispensable tool in modern manufacturing.

Tube laser parts

Tube laser cutting

Tube laser cutting is a specialized method of laser cutting for cylindrical materials, in which a focused laser beam is directed toward the surface of a tube. This beam melts and vaporizes the material along the desired cutting path. While rotating the tube, the machines used in this process simultaneously guide the laser beam along the desired cutting path, allowing a high level of flexibility in manufacturing.

Difference between plate and tube laser cutting

Conventional plate laser cutting is used primarily for cutting flat materials, moving the laser beam over the material in two dimensions, X and Y. However, in tube laser cutting systems, the rotation of the tube or profile section must also be factored in. These machines are thus generally more complex and control multiple axes. Furthermore, with tubes, potential deformation due to the cutting process must be kept in mind, unlike flat plates, in which deformations are usually at the material level.

Laser parts with surface treatment

At FACTUREE, you can also obtain laser cut parts with surface treatment on request. This saves you the logistical effort of ordering from multiple suppliers, having only one contract partner throughout the entire manufacturing process.

Selection of available surface treatments

- Anodizing

- Powder coating

- Black finishing

- Passivating

- Nickel plating

- Galvanizing (zinc plating)

- etc.

- Glass bead blasting

- Polishing

- Electropolishing

- etc.

- (Laser) engraving

- Deburring

- Drilling

- Countersinking

- Thread cutting

- Reaming (fitting)

- Stud welding

- Pressing in

- etc.

Laser cutting – from the prototype to large series

At FACTUREE, you can obtain CNC-machined laser cut parts in any quantity, from a single prototype to mass production. Plus, we can individually optimize your quote for price or delivery time. We will be happy to advise you.

In prototyping, generally every day counts. Online Manufacturing has now become synonymous with speed. Due to our large network of manufacturers, we always have free capacities and can deliver laser parts in as little as 9 working days.

There are also advantages when procuring series laser parts through Online Manufacturing. With the smart selection of a highly specialized manufacturer, large quantities can be produced cost effectively. We would be happy to check free of charge whether we can undercut your current rates.

Framework agreements give businesses long-term price stability for more reliable planning. With FACTUREE, framework agreements for laser parts can be customized and tailored to your needs.

Case study: Ghost Bikes

Components from FACTUREE get into gear with GHOST-Bikes

Online Manufacturer supplies components for attaching batteries to e-mountain bikes of a global bicycle manufacturer

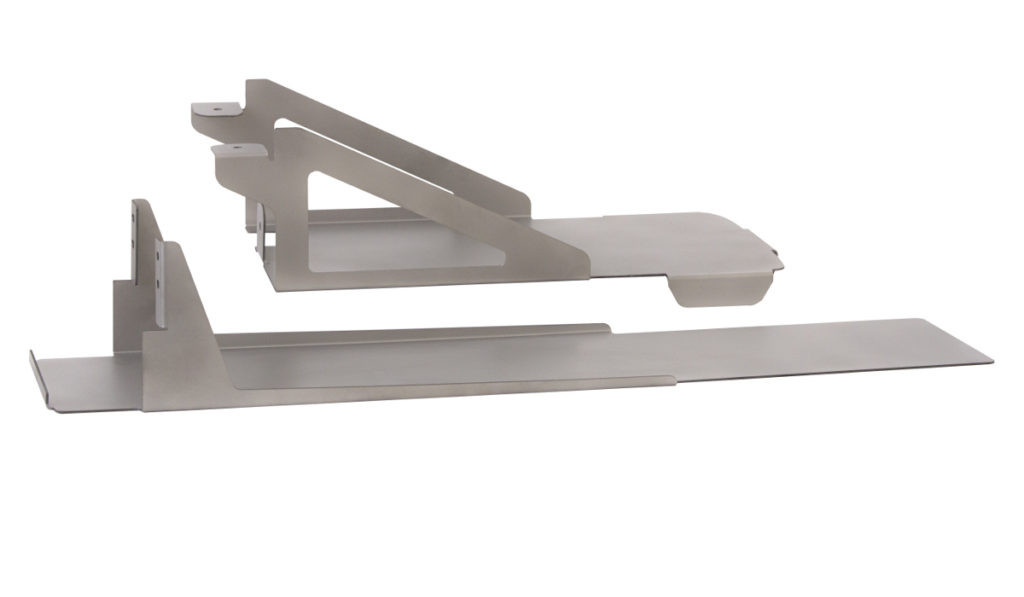

The world has seen a real boom in bicycles since the coronavirus pandemic – and those with gears are booming in particular. However, e-bikes require a complex design with a high level of precision. For an e-bike line of bicycle manufacturer GHOST-Bikes , the Online Manufacturer FACTUREE supplies three key components in serial production. The parts are used to attach and stabilize the battery on the frame of the bicycle. The manufactured components also enable GHOST-Bikes to develop and implement functional technical solutions for prototyping within a very short time.

GHOST-Bikes was founded more than 25 years ago in Waldsassen, Germany, and has become a global company, producing over 150,000 bicycles annually. In addition to gravel and mountain bikes, its portfolio also includes mountain, city and trekking e-bikes.

According to GHOST-Bikes GmbH, the complexity of the products in this field is steadily increasing, in particular due to the boom in the electric bicycle sector. At the same time, demand is increasing. GHOST-Bikes has therefore always looked for optimized manufacturing methods that are more efficient and cost-effective while maintaining very high quality. As a result of this, the company commissioned FACTUREE with the Online Manufacturing of various milled and turned parts, bent sheet metal parts, and individual parts in serial production, for example for their E-RIOT e-mountain bikes. The components are also used to support prototyping.

As an Online Manufacturing company, FACTUREE has access to a large manufacturing network of some 2,000 partners in nearly all areas – including CNC machining, sheet metal processing, 3D printing and surface technology. Around 15,000 machines are constantly available for projects. For GHOST-Bikes, one of the crucial criteria was the fact that FACTUREE can offer many different processes – from turning and milling to sheet metal processing and forging – from a single source and in serial production.

Co-founder and CMO of FACTUREE Benjamin Schwab states, “Some of the components we supply for GHOST-Bikes are bent parts for securely fastening batteries to bicycle frames, for example the battery track that helps prevent rattling while driving and keeps the battery secured to the frame. We also supply a forged part that serves as a connector between the kick stand and the bicycle frame.”

Favorable costs and supply times

Due to its online network, FACTUREE is able to have custom components manufactured with a high level of precision by specialized suppliers and to deliver them quickly. For every request, the most suitable manufacturer is selected and the appropriate manufacturing process recommended. All FACTUREE partner companies are subject to continuous, ISO 9001 certified, data-driven quality management.

GHOST-Bikes chose FACTUREE because the Online Manufacturer ensures very short delivery times and offers all manufacturing techniques thanks to its large network of manufacturers. All components were manufactured quickly and demonstrated a high quality. In addition, the pricing and support were ultimately the deciding factors.