Series production, long-term contracts and large-scale projects at FACTUREE

FACTUREE – The Online Manufacturer provides you with the state-of-the-art procurement of parts - also on a large scale.

As an Online Manufacturer with a large network of manufacturing partners from the fields of CNC machining, sheet metal processing, 3D printing and surface treatments we have access to an almost unlimited number of machines and thus always have available capacities and secure supply chains for complex large-scale projects.

Benefit from individual consultation, short delivery times and competitive prices.

How Online Manufacturing at FACTUREE works

Inquiry

- Easy online inquiry

- Inquiries also possible by email

- Individual consultation by phone or video call

Quoting process

- Offer tailored to your needs

- Competitive prices thanks to large network

- We undercut your current manufacturing costs

Order placement

- More than 2000 specialized manufacturing partners

- AI-supported selection of the optimal manufacturer

- FACTUREE is the sole contractual and contact partner

Manufacturing

- Broadest manufacturing range in the market

- Unlimited production capacity

- ISO 9001 certified quality management

Shipment

- Short delivery times even for large quantities

- Europe-wide express shipping

- 100% climate neutral

From industry to top international research - more than 10,000 satisfied customers

Service range

Manufacturing processes:

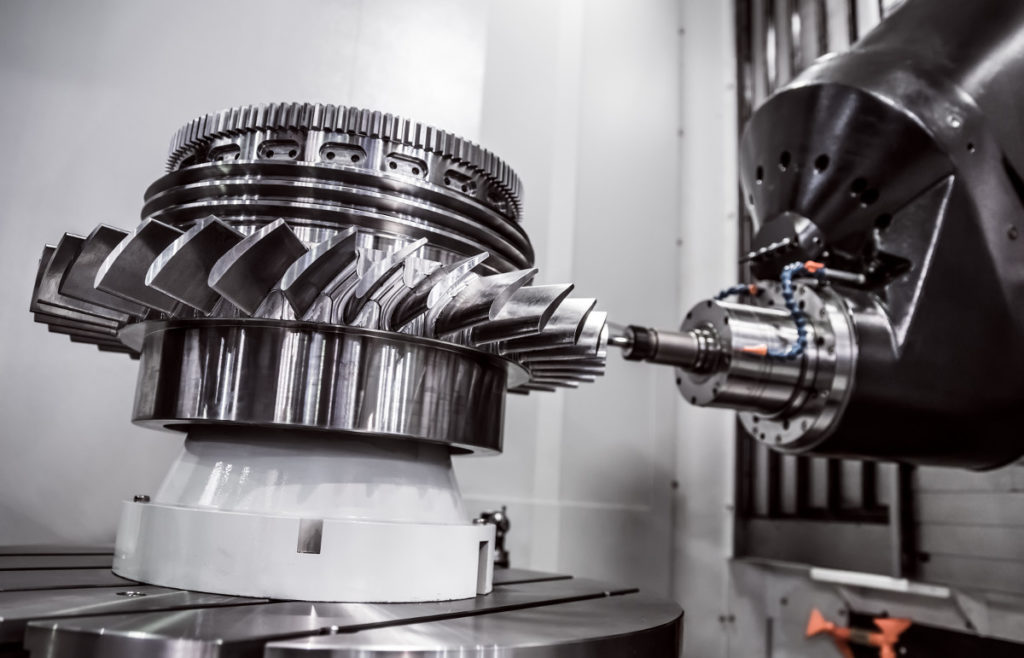

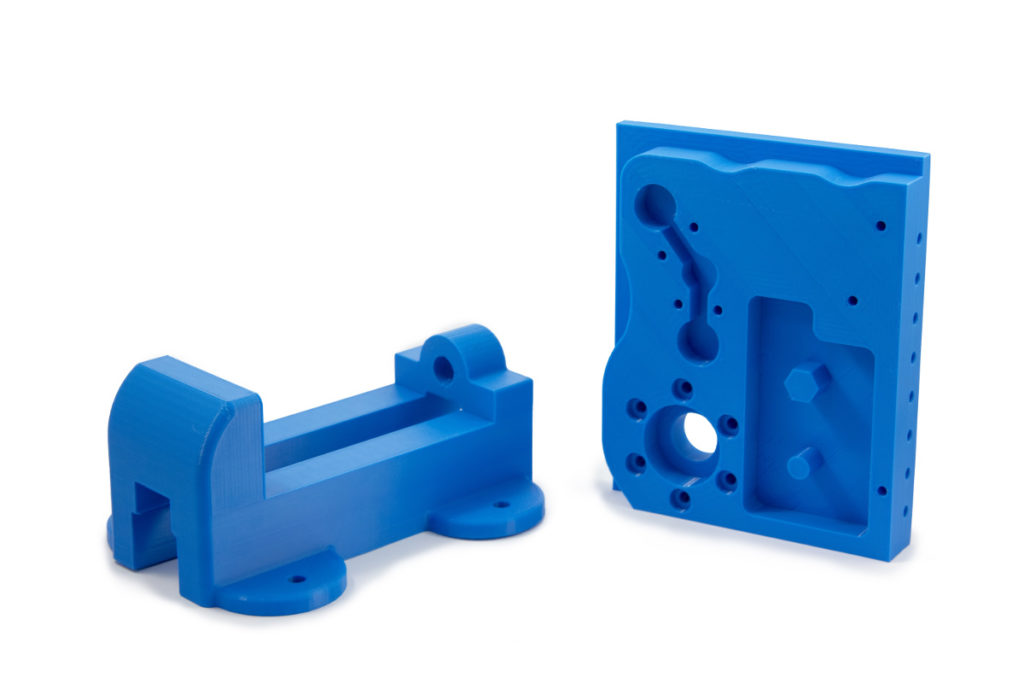

- CNC machining

- Sheet metal processing

- 3D printing

- incl. surface treatments

- Series production

- Long-term contracts

- Large scale projects

Series production

While short delivery time often plays a central role in prototyping, the focus in series production is clearly on price and reliable quality. In many cases, CNC series production is particularly well suited for this, but additive manufacturing is also becoming increasingly relevant.

By using AI-backed supplier matching, we find the most suitable manufacturer for your project in our manufacturing network of over 1000, often highly specialized companies and can therefore guarantee low prices at high quality.

We also check for you, without any obligation or own effort, whether we can undercut your current manufacturing costs – either internally or externally. In more than a half of all cases, we can offer significantly better conditions with the same or superior quality.

Long-term contracts

In case of regular high demand for parts and the necessity of planning security, you can also enter into long-term contracts with FACTUREE.

Benefit from stable prices and particularly attractive conditions with long-term planning.

Contracts can be negotiated individually according to your needs. We will gladly advise you on this.

Large scale projects

At FACTUREE, we can provide you with complex large-scale projects that require individual handling.

We have already successfully executed numerous large-scale projects, such as steel parts for neutron shielding amounting to five tons for CERN (Case Study).

For large-scale projects, submit an inquiry through our inquiry form and select that you would like individual telephone consultation.

Case Study: CERN

FACTUREE produces radiation protection components for the European research center CERN

European nuclear physics laboratory relies on digital procurement of parts for neutron shields

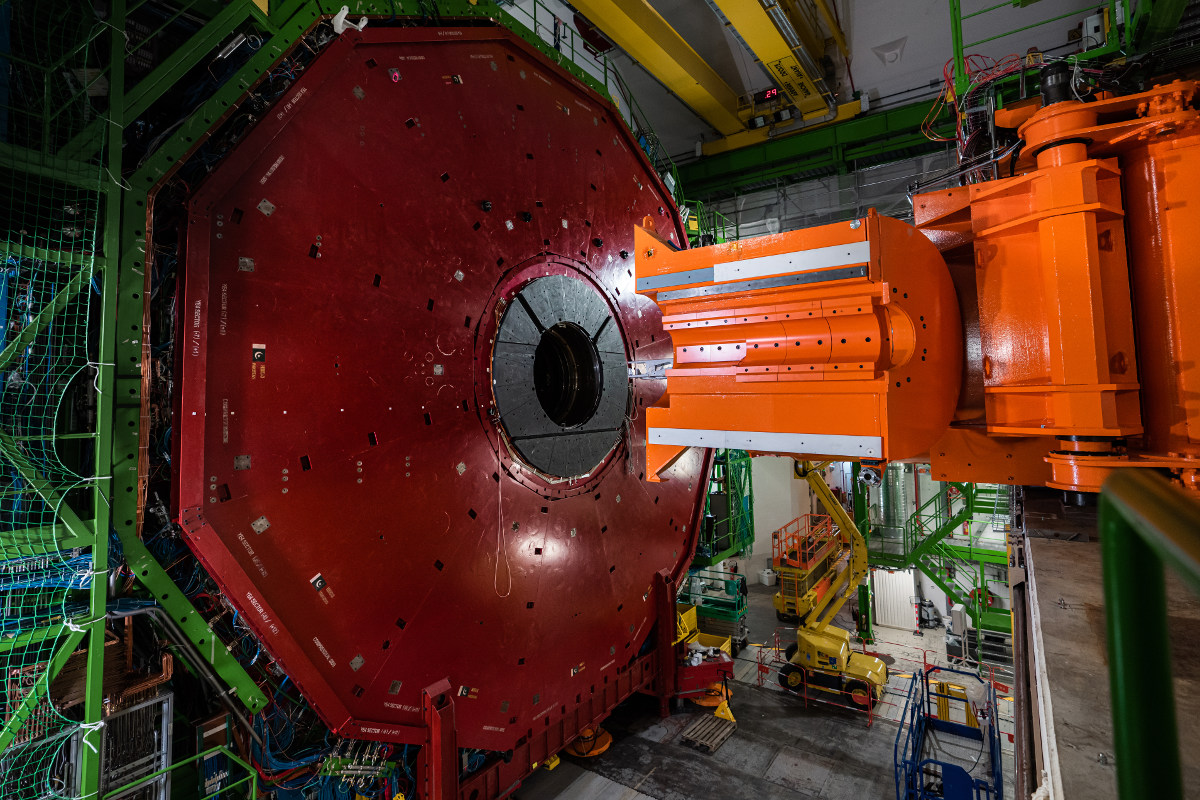

CERN, the European Organization for Nuclear Research, is one of the world’s largest and most renowned centers for basic physics research. The CMS experiment conducted by CERN is considered one of the largest international scientific collaborations in history. For this experiment, CERN entrusted FACTUREE – The Online Manufacturer (www.facturee.de/en) with procuring special parts for the complex CMS particle detector developed specifically for this purpose. In an extensive project, FACTUREE produced steel pipes and plates used in the physics experiment as components for neutron shields.

At CERN (Conseil Européen pour la Recherche Nucléaire) in Geneva, scientists explore the fundamental laws of the universe. The European project was founded in 1954 and has 23 member states, including the United Kingdom and Germany as a founding members. CERN employs more than 12,000 scientists from 85 countries.

Needed quickly: high-quality special protective shield for particle detector

The European nuclear physics laboratory provides its researchers a unique array of particle accelerators. At CERN, the world’s largest and most complex machines are used to research the smallest units of matter – elementary particles.

The Compact Muon Solenoid (CMS) experiment is a particle detector at the Large Hadron Collider (LHC) at CERN in Switzerland. An underground hall in the accelerator ring near Cessy in France hosts the large-scale experiment involving – as of September 2019 – 5000 particle physicists, engineers, technicians, students and assistants from 200 institutes in 50 countries.

Ali Karaki, Mechanical Engineer at CMS/CERN, states: “For this important experiment, we needed a special protective shield, as our previous shields were contaminated with radiation. When searching for a manufacturer, the key factors were procurement time, quality and handling. There are currently only a few companies in Europe that can manufacture large-scale parts precisely and reliably. We have already had positive experiences with FACTUREE in procuring precision parts, sample holders, adapter pieces, etc. and we therefore opted for the online manufacturer for this project as well.”

When awarding the contract for this major project, knowledge of the exact chemical composition of the steel used was also decisive. Lukas Schlicker, Head of Purchasing at cmwk GmbH, explains: “In order to calculate the effectiveness of the protective shields against radiation, you must know the exact chemical composition of the steel batch.

We were able to give CERN the chemical analysis of the batch intended for use in production during the quotation phase. The effectiveness of the protective shields was then simulated and confirmed at CERN.

cwmk GmbH operates as an Online Manufacturer under the FACTUREE brand name. FACTUREE has a broad network of over 1000 production partners across the areas of CNC machining, sheet metal processing, 3D printing, and surface technology. More than 8000 machines are always at the ready for projects, ensuring on-time deliveries. The company has an ISO 9001 certified quality management system.

Fast procurement and cost advantages

FACTUREE produced a total of 5 metric tons of steel pipes and plates for CERN that were used in the CMS experiment as components for radiation protection. The contract also included special features and services, among them the procurement of raw material, processing, painting, assembly and delivery.

Ali Karaki sums up: “The quotation from FACTUREE was fast, as was delivery of the components. We found no defects in the incoming inspection. The costs for the components were around 15% lower than from other providers in Europe. If CERN should ever need components for protective shields such as steel plates or pipes in the future, we will definitely turn to FACTUREE for procurement again.”

Manufacturing technologies

Thanks to a large network of manufacturing partners, FACTUREE covers a wide range of manufacturing services. You can order parts made by CNC machining, sheet-metal processing or 3D printing, as well as subsequent surface treatments.

- Manufacturing technologies

Specifications for milling parts:

- Max. dimensions: L: 7500 mm x W: 3000 mm x H: 2200 mm

- Wall thickness: from 0.2 mm

Specifications for turning parts:

- Length: 0.5mm – 2500mm

- Diameter: 0.5 mm – 1000 mm

General specifications:

- Tolerances: ±0.01mm

Manufacturing processes:

- Cutting

- Laser cutting

- Water jet cutting

- Plasma cutting

- CNC bending

- Deep drawing

- Punching

- Nibbling

- etc.

Specifications for sheet metal parts:

- Max. dimensions: L: 6000 mm x W: 2000 mm

- Sheet thickness: from 0.5 mm

- Tolerances: ±0.02 mm

Manufacturing processes:

- Fused Deposition Modeling (FDM)

- Stereolithography (SLA)

- Multi Jet Fusion (MJF)

- Polyjet

- Selective Laser Sintering (SLS)

- Selective Laser Melting (SLM)

Specifications for 3D printed parts:

- Min. dimensions: L: 3mm x W: 3mm x H: 3mm

- Max. dimensions: L: 1000mm x W: 1000mm x H: 1000mm

- Wall thickness: from 0.2 mm

materials

Benefit from our network with the largest material selection on the market. There is hardly a material that cannot be procured for your production parts. If it cannot be done, we almost always find a suitable alternative.

- Aluminum alloys

- Steel

- Stainless steel

- Brass

- Bronze

- Copper

- Inconel

- Titanium

- etc.

- ABS

- PC

- PEEK

- PEI

- PET

- PETG

- PLA

- Polyamide (Nylon)

- POM

- PP

- Silicones

- etc.

- Standard

- Clear

- Durable

- Flexible

- High Temp

- Polycarbonate-like

- etc.

- Glass ceramic

- Composites e.g. alumides

- Polymer plaster

- Wood

- More materials upon request

Surface treatments

At FACTUREE, you can also receive your parts with subsequent surface treatments. This way, you save the logistical effort of commissioning several service providers and have only one contractual partner for the entire duration of the manufacturing process.

Selection of available surface treatments

- Hardening

- Quenching and Tempering

- Case hardening

- Gas nitriding

- Plasma nitriding

- etc.

- Anodizing

- Hard anodizing

- Black finishing

- Passivating

- Phosphate conversion coating

- Nickel plating

- Galvanizing (zinc plating)

- etc.

- (Laser) engraving

- Polishing

- Grinding

- Sandblasting

- Glass bead blasting

- etc.