Large network + Smart selection + From a single source = Online Manufacturing

As an Online Manufacturer with a network of more than 2,000 manufacturing partners, FACTUREE has access to virtually unlimited capacities for the manufacturing of all kinds of custom parts, thus securing your supply chains.

By using machine learning algorithms, we find the optimal manufacturer in terms of quality, price and delivery time for each one of your projects - from prototype to series production.

FACTUREE is the sole contract partner and contact throughout the whole duration of the project and takes full responsibility for on-time delivery and quality of the parts.

How Online Manufacturing at FACTUREE works

Inquiry

- Easy online inquiry

- Inquiries also possible by email

- Telephone customer service

Quoting process

- Express quotes – often on the same day

- Two-stage technical feasibility check

- Flexible offer optimization regarding price or delivery time

Order placement

- More than 2000 specialized manufacturing partners

- AI-supported selection of the optimal manufacturer

- FACTUREE is the sole contractual and contact partner

Manufacturing

- Broadest manufacturing range in the market

- Unlimited production capacity

- ISO 9001 certified quality management

Shipment

- Consistently short delivery times

- Europe-wide express shipping

- 100% climate neutral

Numerous advantages over conventional procurement of CNC-machined parts

Find out more about the advantages of Online Manufacturing and how you can benefit from it in our latest white paper „The future of parts procurement“

From industry to top international research – more than 15,000 satisfied customers

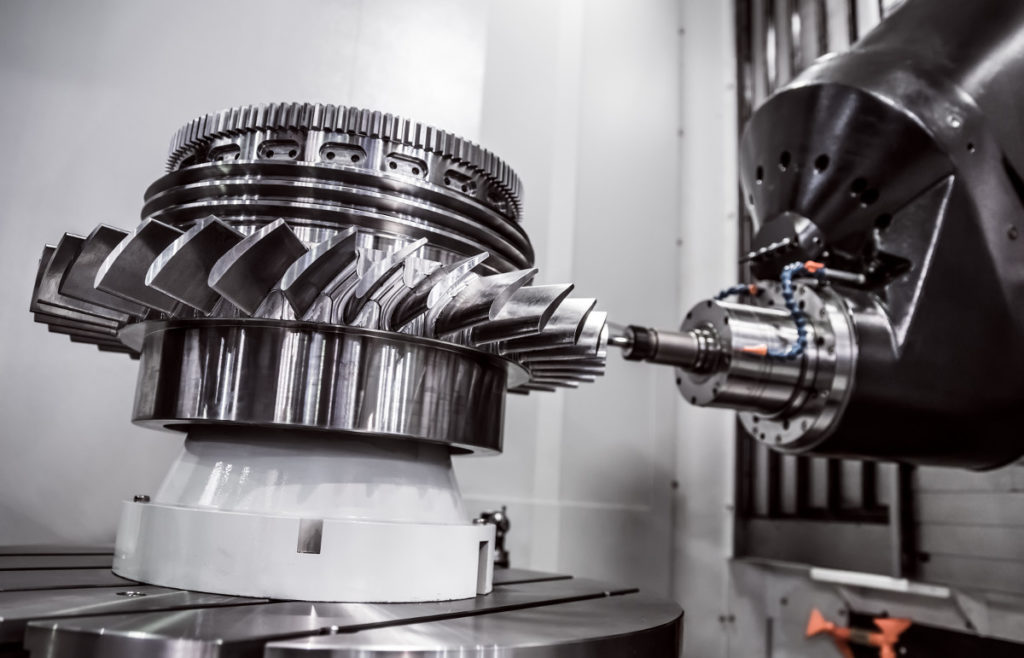

CNC machining

Manufacturing processes:

- CNC milling

- CNC turning

- CNC sheet metal processing

- Largest material selection on the market

- Incl. surface treatments

- Prototyping and large scale mass production

CNC machining processes

From CNC milling to sheet metal processing, FACTUREE is your one-stop shop. Due to our large manufacturing network we cover the complete spectrum of CNC manufacturing. In addition, you can now also choose from various 3D printing processes.

Manufacturing processes:

- 3-axis milling

- 5-axis milling

- Metal and plastics

- Incl. surface treatments

Specifications for milling parts:

- Max. dimensions: L: 7500 mm x W: 3000 mm x H: 2200 mm

- Wall thickness: from 0.2 mm

- Tolerances: ±0.01mm

- Quantity: starting from 1 pcs.

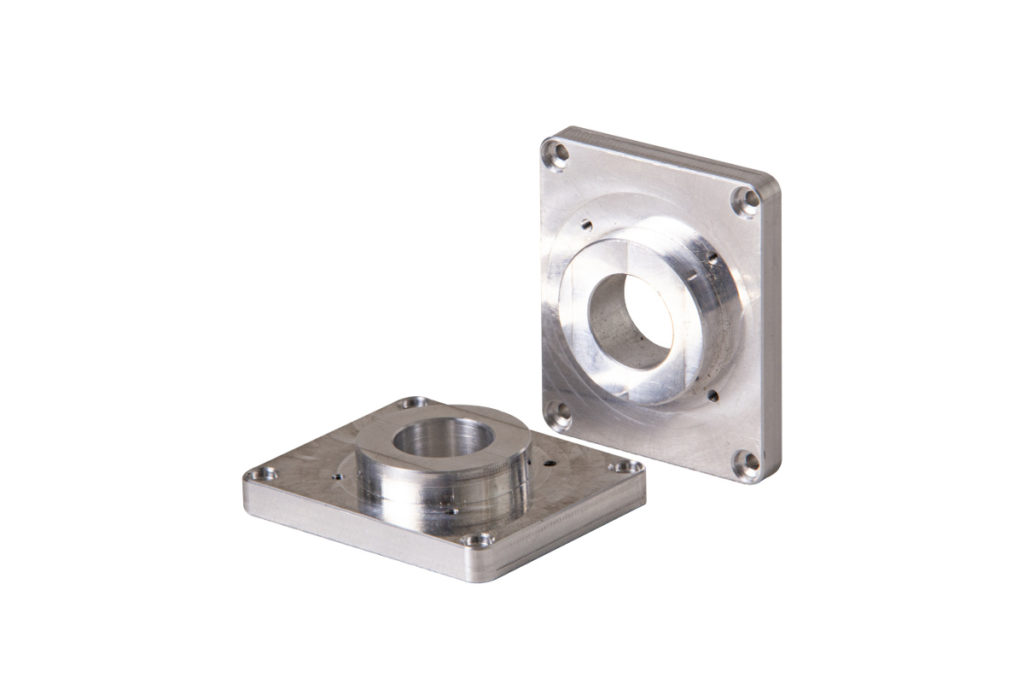

Manufacturing processes:

- CNC machining

- Metal and plastics

- Incl. surface treatments

Specifications for turning parts:

- Length: 0.5mm – 2500mm

- Diameter: 0.5 mm – 1000 mm

- Tolerances: ±0.01mm

- Quantity: starting from 1 pcs.

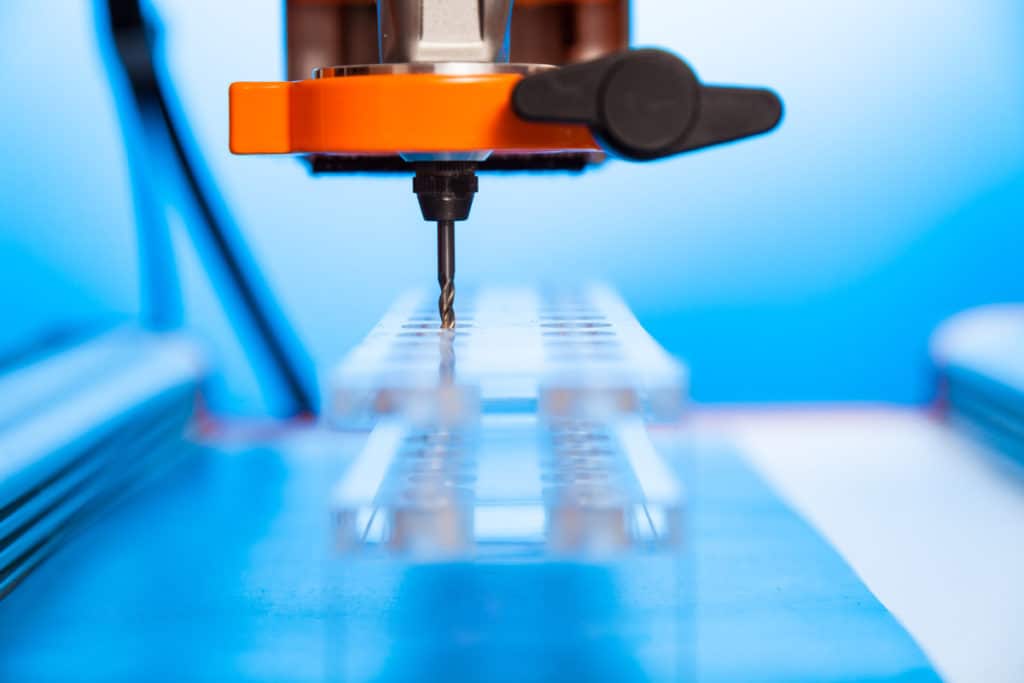

Manufacturing processes:

- Cutting (laser, water jet, plasma cutting)

- CNC bending

- Deep drawing, punching and nibbling

Specifications for sheet metal parts:

- Max. dimensions: L: 6000 mm x W: 2000 mm

- Sheet thickness: from 0.5 mm

- Tolerances: ±0.02 mm

- Quantity: starting from 1 pcs.

Materials for CNC machining

Benefit from our network with the largest material selection on the market. There is hardly a material that cannot be procured at short notice for your CNC-machined parts. If it cannot be done, we almost always find a suitable alternative.

CNC machining of metal

Frequently requested for CNC-machined aluminum parts:

- EN AW-5083 | 3.3547 | AlMg4,5Mn

- EN AW-5754 | 3.3535 | AlMg3

- EN AW-6060 | 3.3206 | AlMgSi0,5

- EN AW-7075 | 3.4365 | AlZnMgCu1,5

Frequently requested for CNC-machined steel parts:

- 1.0037 | S235JRC+C | St37k

- 1.0503 | C45

- 1.4301 | V2A

- 1.7131 | 16MnCr5

Frequently requested for CNC-machined

- Copper parts: OF-Cu | 2.0040

- Brass parts: Ms58 | CuZn39Pb3 | 2.0401

- Bronze parts: CuSn8 | 2.1030

- Titanium parts: Ti Gr 5 | Ti6Al4V | 3.7165

CNC-machining of plastics

Selection of available plastics

- ABS

- PE

- PE-UHMW

- PMMA | Acrylic glass

- PVC

- PVC-U | Hard PVC

- PP

- PS

- PTFE | Teflon

- etc.

PA6

PA66 | Nylon

PBC

PC

PET

POM-C

POM-H

ESD-POM

- etc.

PEEK

PEI

PPSU

- PSU

PVDF

- etc.

- PA6 GF15

PA6 GF30

PA66 GF30

PEEK GF30

POM GF30

PP GF30

PPS GF40

- etc.

Machined parts with surface treatments

At FACTUREE you can procure CNC-machined parts with surface finishes. This way, you save yourself the logistical effort of commissioning several service providers, and have only one contractual partner for the entire duration of the manufacturing process.

Selection of available surface treatments

- Hardening

- Quenching and Tempering

- Case hardening

- Gas nitriding

- Plasma nitriding

- etc.

- Anodizing

- Hard anodizing

- Black finishing

- Passivating

- Phosphate conversion coating

- Nickel plating

- Galvanizing (zinc plating)

- etc.

- (Laser) engraving

- Polishing

- Grinding

- Sandblasting

- Glass bead blasting

- etc.

CNC machining - from prototype to large scale mass production

At FACTUREE you can get CNC-machined parts in all quantities, from single prototypes to mass production. Have your offer individually optimized regarding price or delivery time. We will be happy to advise you.

When it comes to CNC prototyping, often every day counts. Online Manufacturing has become a synonym for speed. Due to our large network of manufacturers, we always have free capacities as well as a short time delivery of 9-12 working days.

Also, large scale production via Online Manufacturing can have advantages. Using smart selection of a highly specialized manufacturers, it is possible to produce high quantities in a cost-efficient way. Let us check free of charge whether we can undercut your current purchase prices.

Framework agreements can offer companies long-term price stability and thus planning security. Frame contracts for CNC-machined parts can be individually designed with FACTUREE, and tailored according to your needs.

Case study: Max Planck Institute for Plasma Physics

FACTUREE supplies components for fusion research facility at the Max Planck Institute for Plasma Physics

Online Manufacturer supports assembly work at the world’s largest stellarator fusion reactor with CNC-machined special parts

Being one of the largest centers for fusion research in Europe with facilities in Garching and Greifswald, the Max Planck Institute for Plasma Physics (IPP) is a flagship project. With its experimental and theoretical basic research, the institute aims to reproduce the physical processes of the sun on Earth and generate energy from the fusion of atomic nuclei.

In this endeavor, the IPP uses the world’s largest and most modern stellarator fusion reactor, Wendelstein 7-X, which is located in Greifswald and began operating in 2015. As a pioneer in international fusion research, the project’s objective is to investigate the suitability of this special type of facility as a power plant in continuous operation. At the heart of the facility are five superconducting coils that generate a magnetic field cage in which a milligram of hydrogen gas is heated to temperatures greater than 100 million degrees to reach the plasma state.

Higher heat output and plasma discharge require special components

The fusion facility is currently being converted so that even higher heat output and longer plasma discharges can be achieved in the next operating phase. For supplying the assembly tools, support structures, tread plates, special parts for scaffolding, and aluminum and stainless components required for the modification work, IPP relies on “FACTUREE – The Online Manufacturer”.

Broad production network ensures short delivery times

FACTUREE is a brand of cwmk GmbH and has an extensive production network in the fields of CNC machining, sheet metal forming, 3D printing, and finishing technology. The company can draw on a broad range of network partners, production technologies, and finishing treatments that enable fast supply times, a high potential for cost savings, and short-term deliveries on schedule. All FACTUREE partner companies are subject to continuous ISO 9001 certified data-driven quality management.

Andree Benndorf, employee in the Department of Assembly Technology at the Max Planck Institute for Plasma Physics (IPP), says: “We requested several quotes in accordance with the German procurement and contract procedures (VOL). FACTUREE provided their quote very quickly, within one to two days. We were impressed by their broad range of services as well as their pricing structures and short delivery times. FACTUREE has met 100% of its delivery dates up to now. We are also very satisfied with the quality of the components and will push to continue this cooperation.”