Experienced marketing expert takes over from Benjamin Schwab

Chantal Kasper is the new Head of Marketing with Online Manufacturer FACTUREE

Berlin, 25. January 2024 - Chantal Kasper is now Head of Marketing at the Online Manufacturer, FACTUREE (www.facturee.de). With over 10 years of experience in marketing and media strategy, she brings extensive expertise with her. She will take over from Benjamin Schwab, who is leaving the company at the end of February on friendly terms. In her new role, Chantal Kasper has set herself the goal of further strengthening the FACTUREE brand and raising the company's profile on the international market.

Chantal Kasper was most recently Head of Brand Marketing & Communication at the online used car platform heycar. Prior to this, she gained valuable experience in marketing at the textile company Walbusch and on the media agency side, where she worked for clients such as Siemens AG. In her new role as Head of Marketing at FACTUREE, she is working to position the platform as the comprehensive one-stop-shop solution for almost all manufacturing inquiries among the target groups.

FACTUREE - a brand of cwmk GmbH - has a production network of around 2,000 partners in the fields of CNC machining, sheet metal processing, 3D printing and surface technology. As a result, the online manufacturer maintains the broadest manufacturing spectrum on the market. More than 15,000 machines are constantly available for projects, ensuring timely deliveries.

One of Chantal Kasper's declared goals at FACTUREE is to further increase brand awareness in the competitive environment. She says: "In doing so, I am focusing on making our offering more visible to both existing customers and potential new customers. My expertise lies particularly in branding, developing, and implementing media strategies and strengthening customer loyalty. This helps me to successfully drive forward marketing initiatives and contribute to the further growth of FACTUREE."

Co-founder and CMO hands over the baton at the end of February

Chantal Kasper succeeds Benjamin Schwab, who will hand over the baton at the end of February. The latter is co-founder of FACTUREE and has helped write the company's successful history to date as CMO. Benjamin Schwab says: "FACTUREE was founded from the living room in 2017 as a real early mover in the DACH region and we coined the term Online Manufacturing. Today, FACTUREE has an eight-figure turnover - and that's without investors. I am proud to have helped shape this exponential growth from the very beginning and will continue to watch it with pleasure - I have found a worthy successor in Chantal. I will always be close to the company, which will always be close to my heart, and I will remain friendly connected to it in an advisory capacity in the background."

Moritz König, Co-Founder and CEO at FACTUREE, says: "We have joined forces to launch and grow FACTUREE and have mastered significant growth steps and pains along the way. We regret that Benjamin Schwab will no longer be an active part of the team and would like to thank him for his great achievements."

Online Manufacturing contributes to sustainable processes at various levels

FACTUREE shows: Online Manufacturing promotes sustainable procurement

Berlin, November 8, 2023 – Sustainability is multi-faceted. Among other things, it refers to a company's ability to operate in the long term while assuming social, environmental and economic responsibility. The procurement process also plays a key role here and should be designed to be both stable and sustainable in a number of areas so as to support these goals. The new form of procurement – Online Manufacturing – promotes this, for example by ensuring the more efficient utilization of machine capacities and conserving resources. The Online Manufacturer FACTUREE (www.facturee.de) shows how this works.

"Procurement today is subject to major challenges and uncertainties. For example, supply chains are susceptible to disruption due to increasing natural disasters, political unrest, or global health crises. Sustainable supply chains are often more diversified and more resilient to disruptions and shocks, as they are usually spread across multiple suppliers and regions. And this is the exact approach that Online Manufacturing supports," explains Benjamin Schwab, Co-Founder and CMO at FACTUREE.

Stable supply chains and pooling of resources through a network

Online Manufacturing follows the network approach. FACTUREE has an extensive production network of around 2,000 manufacturing partners from almost all areas, such as CNC machining, sheet metal processing, 3D printing, casting and forging processes and surface technology. Around 15,000 machines are constantly available for projects. This means that FACTUREE is able to deliver at all times, even in times of crisis. This type of procurement creates a high level of reliability and therefore planning security for customers – two things that support sustainable action and management.

The networking of all participants in the value chain along with simple and short processes for end customers also contribute to sustainability. A procurement platform can bundle purchases from different companies, which offers scaling potential. This can help to optimize transport and reduce emissions. In addition, for example, common sustainability standards and targets can be set for suppliers to make the entire supply chain more sustainable.

Price stability promotes planning security in procurement

The bundling of orders at FACTUREE has another added value for customers: Price advantages. As Benjamin Schwab explains, "we are the price leader in Online Manufacturing. One of the reasons we hold this position is because we purchase large volumes from manufacturers and select the most suitable supplier for the respective order in terms of price, delivery time and quality based on smart algorithms. Furthermore, we do not pass on price increases to our customers. This is a special offer especially in times of rising raw material and energy prices."

If you can rely on stable prices and good conditions, you can plan and operate better in the long term.

Quality for longevity and resource conservation

Another key sustainability factor is quality. High-quality products are more durable and therefore also more sustainable. As they generally need to be replaced or repaired less often, fewer raw materials, energy and labor are required to manufacture new components or products. This leads to a reduction in the ecological footprint.

Waste is also reduced, as high-quality components help to ensure that the end products have less faults, resulting in a lower rejection rate. In addition, energy consumption and emissions are reduced.

"At FACTUREE, a continuously data-driven quality management system, which is certified to ISO 9001, checks and guarantees the high quality of the system, process and product. Quality is a factor that plays a major role for us in terms of sustainability," says Benjamin Schwab.

Efficient distribution of capacities

At a time when resources are becoming increasingly scarce, the efficient allocation of production capacities is also very important. Conventional contract manufacturers can benefit from this by joining the production network of an Online Manufacturer.

Benjamin Schwab says: "At FACTUREE, reliable manufacturing partners with free capacity regularly receive selected requests that match their respective strengths. When capacity utilization is high, manufacturing networks can serve as an extended workbench for companies. From an economic perspective, Online Manufacturing therefore leads to more efficient utilization of machine capacities and thus prevents market imbalances."

Sustainability is the path to climate neutrality

Sustainability and climate protection are inextricably linked. CO2 offsetting is an important tool for companies in managing their emissions. For them, it is about offsetting unavoidable greenhouse gas emissions, among other things. This can also be achieved, for example, by promoting climate-relevant environmental projects through internationally recognized standards. FACTUREE contributes to sustainability through the regular purchase of CO2 certificates and supports international climate protection projects.

More and more buyers in companies are favoring sustainable processes in procurement, be it socially, ecologically or economically. Such a focus can reduce costs in the long term and improve a company's reputation – sustainably.

Profile of FACTUREE – The Online Manufacturer:

cwmk GmbH, based in Berlin, operates under the brand name FACTUREE as the first Online Manufacturer. The company pursues the goal of enabling its customers to procure modern production parts through digitization, automation and networking. FACTUREE has an extensive production network of over 1000 manufacturing partners from the fields of CNC machining, sheet metal production, 3D printing, casting, forging, and surface technology. More than 15000 machines are constantly available for projects. All partners are subject to a continuous data-driven quality management system certified according to ISO 9001. FACTUREE can realize prototyping projects as well as small and large series production. The customer base is located in the most diverse fields such as mechanical engineering, medical technology, model making, robotics, automotive as well as aerospace. Leading industrial companies like Siemens and Parker Hannifin, SMEs, research institutes and universities are among the customers. FACTUREE is active throughout Europe and has a continuously growing number of customers in other European countries.

Further information: www.facturee.de

Online Manufacturer makes important contribution to climate protection with purchase of CO2 certificates.

Ecological power for the island of Sumatra: FACTUREE supports hydropower project in Indonesia

Berlin, October 18, 2023 – Economic development on the Indonesian island of Sumatra has been limited largely due to rudimentary infrastructure and unreliable power supply. A run-of-river power plant on the upper reaches of the Musi River provided a solution. The environmental project by South Pole, developer of international climate protection projects, uses the kinetic energy of the flowing water to supply 700,000 people with renewable energy. The Online Manufacturer FACTUREE (www.facturee.de) supports the environmental project and assumes ecological responsibility by purchasing CO2 certificates. FACTUREE is thus making an important contribution to the region's electricity supply, job creation and economic development.

Indonesia's largest island, Sumatra, is covered by dense tropical forests that provide habitats for countless plants and wildlife. The fertile soil is ideal for growing commodities such as rice, coffee and cocoa. But the growing demand for energy is threatening Sumatra's unique natural ecosystems and calls for new solutions. As part of South Pole's climate protection project, a running hydroelectric power plant was built on the upper reaches of the Musi River near the port city of Bengkulu, which feeds 765,000 megawatt hours of power into Sumatra's power grid every year.

The "Musi River Hydropower Project" not only improves access to electricity on Sumatra, it also significantly supports the sustainable development of the agricultural region.

"Hydroelectric power plants are an important part of the energy transition and help to strengthen the economy of a region. This form of energy generation is clean and environmentally friendly, consumes no raw materials and produces no waste products that are harmful to the environment. We have purchased CO2 certificates from South Pole and thus support developments like this," says Benjamin Schwab, Co-Founder and CMO at FACTUREE, and continues: "Our philosophy is to compensate for unavoidable emissions. We do this by financing climate protection outside our value chain while reducing our environmental footprint."

In addition to quality, the Online Manufacturer FACTUREE, a brand of cwmk GmbH, also focuses on sustainability and climate protection in its actions and regularly supports corresponding projects - such as the "Musi River Hydropower Project".

Hydropower plant supplies 700,000 people with renewable energy

The run-of-river power plant in Indonesia produces sustainable electricity without dams and only by exploiting natural differences in altitude. To avoid any negative impact on agriculture and ecology, water extraction is designed in such a way that existing irrigation systems are not damaged. A reforestation program has been developed to protect the landscape and nature in the project's catchment area. With the hydropower project, South Pole and its stakeholders are addressing various challenges in rural Sumatra, particularly the weak electricity supply. The kinetic energy released can now supply 700,000 people with renewable energy.

Promoting sustainable economic development

In addition to sustainable electricity production, the project brings numerous positive socio-economic developments for the local population. For example, qualified jobs are created.

Benjamin Schwab says: "The hydropower plant has created many jobs and training opportunities for local residents. A share of the project’s profits flows back to the population and has enabled, among other things, the construction of an orphanage, new roads and bridges, and other local infrastructure projects. Farmers, for example, are gaining better access to their rice fields and direct sources of income."

200 million tons of greenhouse gases already eliminated or reduced

As the hydropower project in Sumatra is certified as having above-average commitment, it has been awarded the Verified Carbon Standard (VCS) certification. The program is the world's most widespread standard for the voluntary offsetting of greenhouse gas (GHG) emissions. Companies can offset or compensate for their GHG emissions by purchasing CO2 credits that have already been generated by savings in climate protection projects elsewhere. More than 1300 certified VCS projects have eliminated and reduced more than 200 million metric tons of CO2 and other greenhouse gases to date.

FACTUREE has voluntarily offset its CO2 emissions by purchasing CO2 certificates since the company came into existence. The Online Manufacturer thus promotes sustainability not only with its progressive business model for modern procurement, but also through values such as consistency, environmental awareness and social commitment.

Profile of FACTUREE – The Online Manufacturer:

cwmk GmbH, based in Berlin, operates under the brand name FACTUREE as the first Online Manufacturer. The company pursues the goal of enabling its customers to procure modern production parts through digitization, automation and networking. FACTUREE has an extensive production network of over 1000 manufacturing partners from the fields of CNC machining, sheet metal production, 3D printing, casting, forging, and surface technology. More than 15000 machines are constantly available for projects. All partners are subject to a continuous data-driven quality management system certified according to ISO 9001. FACTUREE can realize prototyping projects as well as small and large series production. The customer base is located in the most diverse fields such as mechanical engineering, medical technology, model making, robotics, automotive as well as aerospace. Leading industrial companies like Siemens and Parker Hannifin, SMEs, research institutes and universities are among the customers. FACTUREE is active throughout Europe and has a continuously growing number of customers in other European countries.

Further information: www.facturee.de

Government funding worth millions of euros enables Online Manufacturer to create new positions in the areas of sales/purchasing, logistics and IT

Online Manufacturing company FACTUREE continues to grow thanks to government investment grant for 115 new permanent jobs

Berlin, September 6, 2023 - The Online Manufacturing company FACTUREE (www.facturee.de) is set to receive millions of euros in funding from the state-owned Investitionsbank Berlin (IBB). The so-called "Joint Task 'Improvement of the Regional Economic Structure' (GRW)" is aimed at companies in the commercial sector. With the investment or wage cost subsidy, IBB supports investment projects to create and secure permanent jobs on behalf of the Berlin Senate Department for Economic Affairs, Energy and Operations. Therefore, FACTUREE now has up to 3 million euros in wage cost subsidies at its disposal and has planned to create 115 new permanent jobs.

The state GRW investment grant supports start-ups and existing businesses in the industrial, construction, trade and service sectors. One of the prerequisites is that sales must be predominantly superregional. FACTUREE is growing steadily and, with its online production, has established an entirely new and promising form of parts procurement that is becoming increasingly important internationally too. FACTUREE sees itself as a reliable partner for German industry and has an increasing number of customers in other European countries.

An investment project of over 15 million euros

FACTUREE's current investment project amounts to more than 15 million euros. The Online Manufacturer's goal is to create 115 long-term jobs by March 2026. The new permanent jobs are to be created in the operational teams of Sales and Purchasing. Capacities in the areas of logistics and IT will also be expanded significantly too. The GRW funding supports this project as it contributes to the improvement of the regional economic structure. The funding rate can be a maximum of 30 percent and relates to an investment period of up to 36 months.

Benjamin Schwab, Co-Founder and CMO at FACTUREE, explains: "We are experiencing a steadily growing number of inquiries, which we can only handle in the long term by expanding our number of employees. The government investment grant gives us the opportunity to do just that. FACTUREE has now been awarded a subsidy of 20 percent. This means that up to 3 million euros will be made available to us by the government, all of which will go towards the cost of wages."

The current investment grant is a form of follow-up financing. In the past, FACTUREE has already been granted government funding of around 1 million euros.

"With the two investment grants, we can access a total funding amount of 4 million euros. The prerequisite is that we fill all 115 positions that we have planned. The signs are very good, because our growth curve is pointing steeply upwards," says Benjamin Schwab.

Bootstrapping since day one

FACTUREE has relied on public funding programs instead of venture capital for its rapid growth. Since its founding, the company has been fully self-financed and thus – unlike most of companies in the industry - operates entirely without investor funding.

"Since the very beginning of our company's history, we have enjoyed the trust of the state and are thus in a position to take advantage of public funding programs such as the “Teilhabechancengesetz” (or the Participation Opportunities Act). Among other things, the government funding enables us to successfully prefinance jobs and create numerous local jobs. This orientation gives us complete control over our company and thus clearly separates us from venture capital-financed competitors," says Benjamin Schwab.

Profile of FACTUREE – The Online Manufacturer:

cwmk GmbH, based in Berlin, operates under the brand name FACTUREE as the first Online Manufacturer. The company pursues the goal of enabling its customers to procure modern production parts through digitization, automation and networking. FACTUREE has an extensive production network of over 1000 manufacturing partners from the fields of CNC machining, sheet metal production, 3D printing, casting, forging, and surface technology. More than 15000 machines are constantly available for projects. All partners are subject to a continuous data-driven quality management system certified according to ISO 9001. FACTUREE can realize prototyping projects as well as small and large series production. The customer base is located in the most diverse fields such as mechanical engineering, medical technology, model making, robotics, automotive as well as aerospace. Leading industrial companies like Siemens and Parker Hannifin, SMEs, research institutes and universities are among the customers. FACTUREE is active throughout Europe and has a continuously growing number of customers in other European countries.

Further information: www.facturee.de

Digital procurement platforms are gaining importance as a state-of-the-art solution for purchasing. Supply chain disruptions are frequent, not only in times of crisis. Further, there is increasing price sensitivity among buyers faced with inflation and rising costs. Benjamin Schwab, CMO of FACTUREE, will also be taking part in the online session from 10:35 – 10:55 and will explain why in some areas Online Manufacturing is far superior to conventional contract manufacturing as the procurement model of the future. He will also address the price advantages of FACTUREE compared to instant pricing suppliers. Take this opportunity to learn more about smart procurement solutions on 7 September 2023 and sign up now.

Berlin Partner, a public-private partnership for promoting business and technology in Berlin, has been a strong supporter for FACTUREE. In the following interview by Berlin Partner, Moritz König, CEO of FACTUREE, provides an insight into this cooperation and presents the Online Manufacturer.

For those who don't know your company – what is it about?

Our full name is FACTUREE – The Online Manufacturer. In 2017, we asked ourselves how the procurement of custom parts could be made easier, faster and more sustainable. Our response was Online Manufacturing. Our concept is based on digitalization, automation and networking. To implement this, we have a production network of around 2000 partners from nearly all fields – including CNC machining, sheet metal processing, 3D printing, casting processes, surface technology and module assembly. Around 15,000 machines are constantly available for projects, giving us the broadest manufacturing range in the market and nearly unlimited capacities. With FACTUREE, small and large series production as well as prototyping projects can be carried out.

For each project, we use AI to select the most suitable manufacturer in terms of quality, price and delivery time. The request process is semi-automated. With our new request tool, for example, ninety-nine items can be requested in less than one minute – simply and hassle-free. Once FACTUREE has received the request, the quote is prepared in just a short time.

Our customers get everything from a single source. We are their only interface and sole contract partner. They no longer have to search for, qualify and onboard suppliers. This reduces the workload as much as possible for the purchasing managers, freeing up time they can use for other tasks. And they can also rest assured that we can always deliver due to our broad network. Furthermore, as the price leader, we also offer the best conditions – a key advantage in times when purchasers‘ price sensitivity is increasing.

How did Berlin Partner support your journey?

Berlin Partner supported us in many ways. Particularly noteworthy was the valuable advice on applying for grants, which now amount to more than four million euros. This allowed us to accelerate our projects and develop new business potential.

We also benefit from Berlin Partner when recruiting international experts. For instance, through the Business Immigration Service and assistance in establishing valuable contacts at events such as Viva Tech and London Tech, where we – arranged by Berlin Partner – were part of the German delegation.

We are very grateful for the support from Berlin Partner and appreciate their strong commitment that helps us achieve our financial and personnel growth targets and enhances our innovative power.

What is your vision for your company?

Our goal is to become THE Online Manufacturer globally – as the partner of choice for custom parts of all kinds. We want every purchaser requiring custom parts and looking for fast procurement to think of FACTUREE first. This is undoubtedly an ambitious goal, but we are convinced that it is feasible. Up to now, we have built up FACTUREE by our own bootstraps. We started successfully around 6 years ago with no investors, today we have two-digit million sales with current growth rates around 100 percent per year.

The bootstrapping strategy definitely posed some unique challenges, but it also forced us to work efficiently and stay focused. Relying on our own resources and striving for financial independence makes us more agile and we can respond to changes more quickly. This approach allowed us to develop our own identity and company culture and enabled us to increase our growth rate and profits at a sustainable pace. At the same time, we learned valuable lessons about efficiency and setting priorities that will benefit us in the long term.

We want to continue to grow and expand organically, of course. This involves building up our team to provide the know-how and capacities needed to manage increasing demand and expand our customer base.

What makes Berlin so special for you as a founder?

Berlin has a rich pool of talent right here, which is a huge advantage of this location for us. It allows us to put together an extremely competent team that makes a significant contribution to our company’s success. Although the start-up and investor landscape undeniably plays an important role in business, we have to stress that we take a different approach as a self-financed company. We focus on developing our resources internally and building on our own strength. This doesn’t mean that we ignore the importance of investors, but we concentrate on our business skills and organic growth.

How did you find new colleagues for your team?

We are proud to be considered an extremely attractive employer, even in the midst of a shortage of skilled specialists. Overall, we are convinced that our investments in the wellbeing of our employees are a key reason we have no real problems finding qualified employees, despite the limited pool of talents. As employer, we understand the needs of our employees and create an environment where they can develop their talent and feel good in the long run.

One major factor is that we consistently focus on our employees’ satisfaction. Fair pay is very important for us and we also offer a number of benefits that greatly exceed those usually offered. For example, we have a cook who makes a delicious lunch every day – completely at the company’s expense.

Work should not be just a task, but also give you joy and fulfillment. Our happiness management ensures that we create a motivating and positive work environment that promotes personal and professional development.

Why is your company also interesting for other Berlin-based companies?

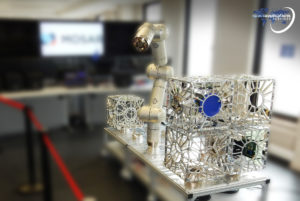

Our company FACTUREE is extremely interesting for manufacturing companies in Berlin, particularly for hardware startups. Especially for young companies that need to use their resources efficiently, our solution is ideal for reducing their workload and allowing them to fully concentrate on their core business.

As Online Manufacturer, we understand the challenges faced by hardware startups and our services are geared to reduce their administrative efforts. From material procurement and production to logistics – we cover the entire manufacturing process, helping the startups to invest their valuable time and energy in advancing their innovative ideas and fleshing out their business models.

Our expertise and experience allow us to be efficient and cost effective, which is especially invaluable for young companies with a limited budget.

As a Berlin-based company, we also understand the local business culture and the dynamics of the startup scene, giving us a real competitive edge. Furthermore, the geographic proximity enables us to develop smooth cooperation with our customers and provide personal support.

Online Manufacturer relies on “sprints” to achieve fast and easy work processes – for customers and employees alike

Online Manufacturer FACTUREE awarded BSFZ seal in recognition of its research and development

Berlin, 5th July 2023 – Continuously driving new developments and concepts is necessary to simplify and accelerate procurement processes. Online Manufacturer FACTUREE (www.facturee.de) has now been awarded the BSFZ seal by the Federal Ministry of Education and Research for its entrepreneurial innovation competence. The company has been committed to research and development to optimize procurement processes from the very start. FACTUREE also focuses on simple processes for employees and has therefore developed its own ERP software.

Online Manufacturing is considered the procurement model for the future, as the platform approach allows covering a very wide manufacturing range while offering free capacities and short delivery times – even in times of crisis. The business model of FACTUREE, a brand of cwmk GmbH, is based on the optimal matching of component requirements with production by German and international manufacturers.

The company facilitates simple processes for their employees as well, ultimately leading to faster reaction times that benefit customers. For example, FACTUREE has expedited the development of a new value creation process and its digital implementation, resulting in a self-developed ERP system. Benjamin Schwab, co-founder and CMO of FACTUREE, states: “In the early days of our company, we were faced with the decision whether to use an existing ERP system or to develop our own. We decided on an in-house solution and programmed a cloud-based ERP system that we eventually launched. This research and development project has now been awarded the BSFZ seal.”

BSFZ recognizes the innovation competence of FACTUREE

The certifying body for research grants (BSFZ) awards the seal only to companies that are eligible for research grant funding – in this case for developing the ERP system for process management.

Benjamin Schwab says, “We started out small and have been self-financed from the very beginning. In the first phase after establishing the company, individual business processes were still handled using Excel sheets and universal software tools. Many companies in our sector use ERP systems for order management, but they prove to be unsuitable when several thousand projects have to be handled simultaneously by up to 40 employees. This is why we developed our own ERP software, designed for scalability and high availability.”

Agile software development and bottom-up feedback

FACTUREE continuously develops tools that simplify processes for employees and customers. The request tool that we recently launched, for example, is a way to reduce the digital request process to a minimum. The extremely fast request and readout of drawings by FACTUREE significantly reduces the workload of purchasers. Up to 99 items can be requested in less than a minute with just a few clicks. The request tool forms an interface with the custom developed ERP system that FACTUREE uses for order management.

“At FACTUREE, what we call sprints determine our daily routine. We have extremely short development times of 14 days and can implement our customers’ demands in a very short time. This is where we win over many purchasers. To be able to do this, we depend greatly on agile software development and bottom-up feedback. Our employees are thus involved in the development of the software that they work with every day. This approach is another feature of our open corporate culture,” says Benjamin Schwab.

Characters: 3,644

Profile of FACTUREE – The Online Manufacturer:

cwmk GmbH, based in Berlin, operates under the brand name FACTUREE as the first Online Manufacturer. The company pursues the goal of enabling its customers to procure modern production parts through digitization, automation and networking. FACTUREE has an extensive production network of over 1000 manufacturing partners from the fields of CNC machining, sheet metal production, 3D printing, casting, forging, and surface technology. More than 15000 machines are constantly available for projects. All partners are subject to a continuous data-driven quality management system certified according to ISO 9001. FACTUREE can realize prototyping projects as well as small and large series production. The customer base is located in the most diverse fields such as mechanical engineering, medical technology, model making, robotics, automotive as well as aerospace. Leading industrial companies like Siemens and Parker Hannifin, SMEs, research institutes and universities are among the customers. FACTUREE is active throughout Europe and has a continuously growing number of customers in other European countries.

Further information: www.facturee.de

Request up to 99 items easily in less than one minute with new request tool

Online Manufacturer FACTUREE speeds up order requests for lightning-fast, easy procurement processes

Berlin, 14 June 2023 – Time is an important criterion for procuring custom parts – starting from when the request is made. Online Manufacturer FACTUREE (www.facturee.de) has reduced the effort for making digital requests to a minimum by developing a new request tool that greatly accelerates quote generation. If technical drawings are available, the information they contain, such as the material, do not need to be selected again. The extremely fast request and readout of drawings by FACTUREE considerably simplifies the buyer’s task. For example, up to 99 items can be requested in less than one minute with just a few clicks.

Fast, easy processes are absolutely essential in today’s procurement practice. Online Manufacturing perfectly matches the requirements as the concept is based on digitalization, automation and networking. With demand-driven production and the rapid provision of components, it also opens up new degrees of freedom. However, with some providers of this state-of-the-art form of procurement, buyers still have to go through elaborate request processes to obtain a quote.

Instant pricing tools, which are used by several Online Manufacturers, make the process even more complicated, because in order to obtain a price immediately using an instant pricing tool, the person making the request must first transfer all relevant information manually to an input form – although the information is generally already available in the technical drawing. And in case there are many items, the input process and uploading the files can be very time consuming.

Benjamin Schwab, co-founder and CMO of FACTUREE, explains, “Getting a quick quote from an instant pricing tool comes at the ‘expense’ of more effort on the customer’s part. FACTUREE has therefore taken a different route from the start. Our request process has always been easy and designed with the customer in mind – we have now optimized it even more and reduced it to a minimum, significantly decreasing the effort required by our customers. It is not even necessary to create an account to make a request. Our recently launched request tool has already been very well received.”

Request 99 items with just a few clicks

When developing the new request tool, it was important for FACTUREE to reduce the time actually needed for users to make the request as much as possible and to make it more user friendly – for example through the modern, intuitive design. The request tool automatically captures all available information uploaded by the person making the request – CAD files and technical drawings in PDF format, for example. It is not necessary to laboriously fill in different positions for the request – matching of 3D and 2D data is done automatically.

“The extremely fast request and readout of drawings by FACTUREE significantly reduces the customer’s workload. With our new request tool, ninety-nine items, for example, can be requested in less than one minute – simply and hassle-free. We will be successively increasing the maximum possible number of items and requests for volume pricing can also be submitted easily. Unlike in competitors’ tools, this can be done with a single click in our tool. This makes the request not only considerably faster, but also much easier than many buyers have been used to. All of this facilitates the faster generation of a quote,” says Benjamin Schwab.

Once FACTUREE has received the request, the quote is generated within a short time. The quote is generally sent the same day but guaranteed within 48 hours. FACTUREE is able to make an express quote thanks to a high degree of automation, e.g. for readout and classification of CAD files. The additional review of the quote by an engineer ensures a reliable calculation despite the speed with which it was prepared.

Characters: 3,967

Profile of FACTUREE – The Online Manufacturer:

cwmk GmbH, based in Berlin, operates under the brand name FACTUREE as the first Online Manufacturer. The company pursues the goal of enabling its customers to procure modern production parts through digitization, automation and networking. FACTUREE has an extensive production network of over 1000 manufacturing partners from the fields of CNC machining, sheet metal production, 3D printing, casting, forging, and surface technology. More than 15000 machines are constantly available for projects. All partners are subject to a continuous data-driven quality management system certified according to ISO 9001. FACTUREE can realize prototyping projects as well as small and large series production. The customer base is located in the most diverse fields such as mechanical engineering, medical technology, model making, robotics, automotive as well as aerospace. Leading industrial companies like Siemens and Parker Hannifin, SMEs, research institutes and universities are among the customers. FACTUREE is active throughout Europe and has a continuously growing number of customers in other European countries.

Further information: www.facturee.de

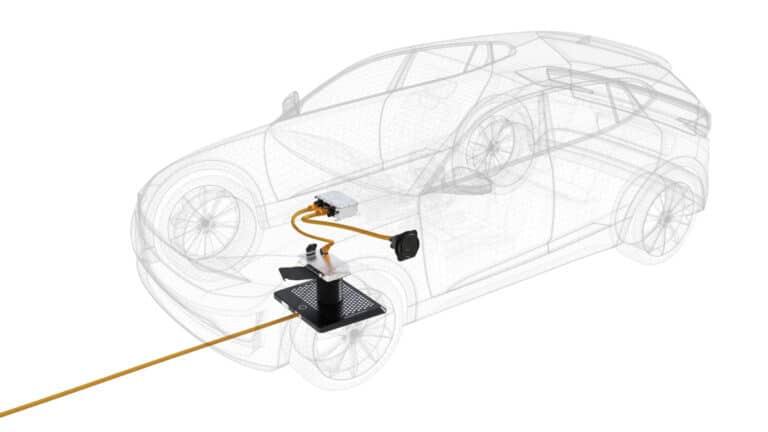

The switch to e-mobility is also taking shape in Austrian cab fleets. This year, ten cab ranks and 66 e-vehicles will be retrofitted with "Matrix Charging" in Vienna and Graz as part of the "eTaxi Austria" project. The automated conductive charging technology was developed by the high-tech company Easelink. For the globally unique pilot project, FACTUREE is supplying various turned and milled parts made of aluminum. They are installed in the integrated "Matrix Charging Connector". During the charging process of an eTaxi, the connector is automatically lowered from the vehicle underbody and connected to a charging pad at the parking lot for charging.

According to the national energy and climate plan, only zero-emission cabs and rental cars will be allowed in Austria from 2025. This measure paves the way for e-mobility. The stated goal is to reduce emissions and improve the quality of life in cities. However, previous eTaxi initiatives have shown that trips to charging stations as well as on-site charging times lead to uneconomic waiting times. The eTaxi Austria project aims to remedy this situation and relies on automated charging directly at charging stations. This avoids interruptions to get to the next charging station and makes the economic operation of electric cabs possible.

Automated charging, a precursor to autonomous driving

The eTaxi Austria project supports the switch of Vienna and Graz cab fleets to e-mobility primarily by providing charging options at the cab stand. Among others, the high-tech company Easelink, headquartered in Graz, is involved in the ambitious project. Over 60 eTaxis in the Vienna and Graz area will be equipped with the automated charging technology "Matrix Charging" developed by Easelink. Users of an e-car are relieved of having to plug in and unplug the vehicle thanks to the special technology. Easelink's goal is to standardize automated charging and thus prepare the e-fueling process for autonomous driving as well.

The Matrix Charging System consists of two main components. Its compact design allows the Matrix Charging Connector to be easily integrated into the underbody of an electric vehicle. The vehicle unit is joined by an infrastructure unit directly at the parking space, the Matrix Charging Pad. As soon as the e-vehicle parks above the Charging Pad at the parking lot, the Connector is automatically lowered by the e-vehicle and physically connected to the Charging Pad at the cab stand. The charging process is automated without the driver having to leave the e-vehicle.

FACTUREE supplies important components for the core element of the charging system

FACTUREE supplies important components for the core element of the charging system For one of the two core components of the conductive charging system, the Matrix Charging Connector, the online manufacturer FACTUREE supplies various small turned and milled parts made of aluminum. Easelink benefits from great flexibility and plannability through the cooperation. This is because FACTUREE draws on a wide range of network partners, manufacturing techniques and surface treatments. As a result, the online manufacturer can constantly offer a very wide range of materials and has virtually unlimited production capacities - this is a major competitive advantage in times when supply problems are more frequent for classic contract manufacturers due to global crises.

The Matrix Charging System can already be retrofitted to the most common electric vehicles on the market. The eTaxi Austria project is preparing the rollout of the automated charging infrastructure, thus setting the course for the mobility turnaround.

Online Manufacturer takes part in scientific project for the prevention of mental illnesses in the work environment

FACTUREE promotes mental health of personnel through model project “Soul Office”

Berlin, 15th May 2023 – Incapacity for work due to mental issues can quickly lead to suffering and high costs. Prevention is therefore key for employees and companies. FACTUREE (www.facturee.de) supports measures to strengthen and restore mental health in the work environment. The Berlin-based Online Manufacturer is therefore taking part in the model project “Soul Office” (souloffice-berlin.de) of the non-profit company KOPF, HAND + FUSS gGmbH (KHuF). Here, employees get the chance to develop and strengthen coping strategies with the help of psychological support, peer counseling and coaching elements. FACTUREE employees can work remotely in KHuF’s coworking space TUECHTIG and take advantage of mental support and coaching there.

A fragile mental state can lead to burnout, depression, anxiety or high stress levels. As mental health affects all areas of life, it determines not only individual wellbeing, but professional performance as well. This has an impact on the ill person on the one hand, but also their family, co-workers and employers.

Benjamin Schwab, co-founder and CMO of FACTUREE, explains, “Employers have a responsibility for the health of their employees and considerable influence on their mental health. In a rapidly growing company such as FACTUREE, for example, the workload is constantly high, placing corresponding demands on the employees. To prevent the workload from impairing mental health and to create a balance, we are taking part in the new project ‘Soul Office’. In this way, we support our employees in maintaining a well-balanced mental state to better cope with stressful situations.”

In the “Soul Office” in Berlin, employees can pursue their work and get psychological support. Further, peer counseling and coaching elements are part of the concept. The goal is to develop and strengthen personal coping strategies directly in the work setting.

Prevention as a pillar of corporate health management

“Soul Office” is a model project of KOPF, HAND + FUSS gGmbH. The program addresses employees who are already ill as well as those who feel that their capacity for work could be at risk because of mental stress and would like to prevent deterioration or illness. Complementing the workplace in the office or at home, the project is understood to be a further element of corporate health management. As part of this initiative, the Online Manufacturer FACTUREE uses a variety of rooms in KHuF’s inclusive coworking space TUECHTIG where employees can work remotely and engage in the “Soul Office” program.

“The ‘Soul Office’ is a place for personal encounters and exchange of ideas. It provides a protected space for dealing with issues that trigger illness and fosters hope and confidence. Because mental illnesses are becoming more common in our fast-moving society, employers should advocate for this issue in general and focus on prevention,” says Benjamin Schwab.

The project includes group settings, short workshops and individual counseling, for example. Working is embedded in a fixed daytime structure. Over a period of several weeks, long-term coping strategies can thus be developed in the work setting and self-care skills can be consolidated. The psychological and psychoeducational formats involved are guided by psychologists and recovery coaches.

Tobias S., a freelancer, is taking part in the Soul Office program. He says, “The Soul Office has taught me how important self-care is. This means in practice that I am more aware and stricter when it comes to taking breaks, giving rise to new ideas and impetus. I have also acquired the ability to structure my work day better and can thus focus more on my work. Additionally, I have learned to manage my urge for perfectionism and accept that good performance is enough. These and other aspects greatly affect my wellbeing and my productivity.”

Corporate prevention prevents longer periods of incapacity for work

The investments made by employers in early prevention contribute primarily to maintaining the mental health of employees, but they also have an economic aspect. Benjamin Schwab explains, “Corporate prevention comes before intervention, from the economic standpoint as well. Impaired mental health leads to frequent days of sick leave and longer absences due to illness, so the approach benefits all involved. The model project also closes a gap. Previously, in most programs in this area, recovery took place in private life, away from the workplace, although there is a direct link between work and health. By participating in the project, we would like to send a signal and counteract the stigma of mental illness.”

Characters: 4.824

Profile of FACTUREE – The Online Manufacturer:

cwmk GmbH, based in Berlin, operates under the brand name FACTUREE as the first Online Manufacturer. The company pursues the goal of enabling its customers to procure modern production parts through digitization, automation and networking. FACTUREE has an extensive production network of over 1000 manufacturing partners from the fields of CNC machining, sheet metal production, 3D printing, casting, forging, and surface technology. More than 15000 machines are constantly available for projects. All partners are subject to a continuous data-driven quality management system certified according to ISO 9001. FACTUREE can realize prototyping projects as well as small and large series production. The customer base is located in the most diverse fields such as mechanical engineering, medical technology, model making, robotics, automotive as well as aerospace. Leading industrial companies like Siemens and Parker Hannifin, SMEs, research institutes and universities are among the customers. FACTUREE is active throughout Europe and has a continuously growing number of customers in other European countries.

Further information: www.facturee.de

Semi-automated generation of quotes with long-term validity provides quick and easy procurement for buyers with planning security and lower prices

FACTUREE reveals: Instant pricing in Online Manufacturing does not simplify things

Berlin, April 13th 2023 – The global market for custom parts is worth billions of euros. Conventional contract manufacturing is still in the lead but is getting more and more competition from the Online Manufacturing concept. There are, however, great differences among providers in Online Manufacturing – for example with respect to the request procedure, pricing and validity of quotes. Many providers use instant pricing, but this involves more effort on the customer’s part and higher prices. Online Manufacturer FACTUREE (www.facturee.de) explains the reasons and shows how they do things differently.

Independence and reliability were never more important for buyers. In times of supply chain disruptions and ever more rapid changes in markets, they need procurement channels featuring both agility and stability. Conventional contract manufacturing cannot ensure these to the extent required, but Online Manufacturing can. The concept has already proven itself to be the procurement model of the future. Online Manufacturing is based on digitalization, automation and networking and is far superior to conventional forms of procurement. Manufacturing capacities can be easily reallocated to meet changing market conditions. Providers such as FACTUREE are therefore always in a position to deliver, making supply chains reliable and resilient for customers.

Not all Online Manufacturers are equal

While the percentage of Online Manufacturers in the market is still very small, the potential is large and growing. However, there are big differences within the market of Online Manufacturers. Some of them, for example, use instant pricing tools that calculate prices immediately, but ultimately mean more effort and higher costs for customers.

Benjamin Schwab, co-founder and CMO of FACTUREE explains, “To get a price using an instant pricing tool, all relevant information must be entered manually into a form by the person making the request – a very time-consuming process. For large requests with more than 30 items, this can take up to half an hour. Most people don’t have time for this. Getting a quick quote thus comes at the “expense” of the customer’s time. Plus, prices are nominally higher due to the safety buffer.”

FACTUREE does not use instant pricing like other providers in the sector. “In more than 80% of cases, we are able to undercut instant pricing offers that competitors give our customers. For our quotes, we consider and optimize the time actually needed by the user to make the request,” says Benjamin Schwab.

FACTUREE relies on semi-automated quotation and automatic readout and classification of CAD data. Every quote is checked by employees for plausibility. The requests are not restricted to the system, but can also be sent by email, for example.

FACTUREE offers a 14-day period of validity for quotes, which the provider can maintain even in a tense market situation. After the request is received, the quote is often made the same day – but guaranteed within 48 hours.

Increasing price sensitivity among buyers

Under the current conditions and indications, buyers develop a certain level of price sensitivity. This gives an advantage to Online Manufacturers who can offer the best package of price and performance. “We benefit from this development because we are the price leaders in Online Manufacturing. We have this position among other reasons because we purchase large volumes from manufacturers and select the most suitable supplier for the order in terms of price, delivery time and quality based on smart algorithms. We also do not pass on higher prices to our customers, which is rare in times of rising prices for raw materials and energy,” states Benjamin Schwab.

By carefully selecting manufacturers, FACTUREE is able to compensate for effects in the market and react flexibly to new developments. This is possible on the one hand due to the platform approach in which customers’ projects can be bundled and also due to the AI-based selection of the most suitable manufacturer.

FACTUREE has a manufacturing network of around 2,000 partners from nearly all areas and the widest range of manufacturing in the market. The request process is semi-automated, ensuring quick quotes. No registration or system integration is required and there are no participation costs.

“Customers can access our model very easily. There is no need to search for suppliers or to qualify and onboard them. Customers can purchase efficiently and concentrate on their core business. In summary, with Online Manufacturing, we support the agility required today while also ensuring reliability and relief, both in the financial sense and regarding the procurement processes,” concludes Benjamin Schwab.

Characters: 4,948

Profile of FACTUREE – The Online Manufacturer:

cwmk GmbH, based in Berlin, operates under the brand name FACTUREE as the first Online Manufacturer. The company pursues the goal of enabling its customers to procure modern production parts through digitization, automation and networking. FACTUREE has an extensive production network of over 1000 manufacturing partners from the fields of CNC machining, sheet metal production, 3D printing, casting, forging, and surface technology. More than 15000 machines are constantly available for projects. All partners are subject to a continuous data-driven quality management system certified according to ISO 9001. FACTUREE can realize prototyping projects as well as small and large series production. The customer base is located in the most diverse fields such as mechanical engineering, medical technology, model making, robotics, automotive as well as aerospace. Leading industrial companies like Siemens and Parker Hannifin, SMEs, research institutes and universities are among the customers. FACTUREE is active throughout Europe and has a continuously growing number of customers in other European countries.

Further information: www.facturee.de

State-of-the-art form of procurement makes an important contribution to agile and highly flexible production

FACTUREE demonstrates: Online Manufacturing promotes agile manufacturing

Berlin, 23 February 2023 – The factory of the future is highly flexible and agile. Agile manufacturing is the key that enables companies to react quickly and effectively to the ever more rapid changes in customer needs and market conditions. It also has the potential to increase production efficiency, reduce costs and enhance value creation. Online Manufacturer FACTUREE (www.facturee.de) supports agile manufacturing: The procurement concept of Online Manufacturing provides companies with the agility and flexibility required to improve their planning process.

Today’s industrial production has to keep pace with increasingly dynamic changes and respond to many different customer needs. Requirements are becoming greater and more complex on the one hand, and on the other hand, they are also changing more rapidly. This requires agile and customized production that allows smaller batch sizes and avoids procurement difficulties. Fast, reliable procurement of components plays a significant role in this process, for which a modern form of procurement – Online Manufacturing – is ideally suited.

Manufacturing of the future is highly agile and flexible

Benjamin Schwab, co-founder and CMO of FACTUREE, explains: “Manufacturing of the future must be highly agile and flexible. Agile manufacturing meets this requirement as it reacts almost in real time to change factors without reducing the quality of throughput or exceeding an allocated budget. We support this approach with our concept of Online Manufacturing where we have parts produced on demand and deliver them at a rapid pace. Our customers thus receive the exact quantity of custom-made components needed and have a greater scope for action.”

One of the goals of Online Manufacturing is to prevent or reduce dependence. This procurement form is based on digitalization, automation and networking, bundling the strengths of different manufacturing specialists on a B2B platform. With a network of some 2,000 manufacturing partners from nearly all areas, FACTUREE offers a wide range of manufacturing techniques and surface treatments. Using AI, the most suitable manufacturer for each request is identified. For buyers, this means reliable and flexible procurement in times of crisis, as the risk of production and delivery problems is extremely low. And getting started is also easy thanks to the simple and digital request and ordering processes. Further, Online Manufacturing offers price stability and price advantages.

Benjamin Schwab adds, “Online Manufacturing platforms and their ecosystems are becoming increasingly more relevant with respect to agile manufacturing because they meet the requirements of modern procurement. The demand-based production or supply of components opens up new levels of freedom. With this purchasing strategy, in addition to the aspect of flexibility and fast delivery, companies are able to achieve considerable savings, large gains in efficiency and better plannability.”

Not at the expense of quality

At the Online Manufacturer, a continuous data-driven, ISO 9001 certified quality management system checks and ensures high system, process and product quality. The logistics partners are also assessed and selected based on reliability.

“Agile manufacturing focuses on satisfying customer demand using flexible production practices. This means that customer requirements must be fulfilled, without leading to loss of quality or additional costs. Our concept of Online Manufacturing therefore perfectly meets the current and future needs of manufacturing companies. We help them react to changes in the market flexibly and with the highest quality – not only in times of crisis,” concludes Benjamin Schwab.

Número de caracteres: 4.227

Profile of FACTUREE – The Online Manufacturer:

cwmk GmbH, based in Berlin, operates under the brand name FACTUREE as the first Online Manufacturer. The company pursues the goal of enabling its customers to procure modern production parts through digitization, automation and networking. FACTUREE has an extensive production network of over 1000 manufacturing partners from the fields of CNC machining, sheet metal production, 3D printing, casting, forging, and surface technology. More than 15000 machines are constantly available for projects. All partners are subject to a continuous data-driven quality management system certified according to ISO 9001. FACTUREE can realize prototyping projects as well as small and large series production. The customer base is located in the most diverse fields such as mechanical engineering, medical technology, model making, robotics, automotive as well as aerospace. Leading industrial companies like Siemens and Parker Hannifin, SMEs, research institutes and universities are among the customers. FACTUREE is active throughout Europe and has a continuously growing number of customers in other European countries.

Further information: www.facturee.de

The future of purchasing series parts lies in platforms and ecosystems

Online Manufacturing: FACTUREE offers procurement advantages in series

Berlin, 18 January 2023 – Companies that produce in series are in an unprecedented situation with respect to procurement. Uncertainties and crises lead to difficult conditions, often making even short-term planning impossible. At the same time, digitalization requires a realignment and response to constantly changing competitive situations. Online Manufacturer FACTUREE (www.facturee.de) reveals new avenues for series production. Adopting the Online Manufacturing approach facilitates secure and flexible procurement, price stability and advantages, high quality and simplified digital request and ordering processes, for example.

When procuring series parts, reliability – through long-term availability, consistently high quality and stable prices – is indispensable. However, there are frequently shortages of raw materials. Sweeping crises such as the coronavirus pandemic and the Russia-Ukraine war have an additional highly negative effect on international supply chains and trade flows in the already difficult procurement situation. As a consequence, prices for raw materials are rising, and on top of this energy costs are soaring.

Breaking up dependencies and blockades

The current development also affects prices for material dealers and contract manufacturers, severely aggravating conditions for industrial buyers. Price increases are especially painful for large series production. The production and supply problems faced by conventional contract manufacturers make manufacturers aware of their dependence and inhibit the agility they need.

Co-founder and CMO of FACTUREE Benjamin Schwab states, “In many areas of industry, conventional contract manufacturing has reached its limits, leading to an increasing shift to alternative procurement and sales markets. Equivalent substitution of critical and finite resources is also becoming more and more relevant. Additionally, manufacturers seek to increase the efficiency of their manufacturing processes.”

Greatly reduced risk of supply shortages and delays

Online Manufacturing is the expression of a shift in procurement strategy. This modern form of procurement simplifies request and ordering processes and keeps the risk of supply shortages and delays significantly lower than is possible with conventional contract manufacturing. An Online Manufacturer with a large network of manufacturing partners can adapt more quickly to prevailing circumstances – for example by reallocating manufacturing capacities. Supply bottlenecks are minimized and challenging large-scale projects, for example in CNC series production, are made possible.

Benjamin Schwab says, “In series production, it is becoming ever more important to utilize the new potential of digital value creation. The concept of Online Manufacturing bundles the strengths of different manufacturing specialists on a B2B platform, resulting in a wide range of network partners, manufacturing techniques and surface treatments. Based on an AI-supported selection process, the most suitable manufacturer can be found for every requirement. For purchasing in series production, this means reliable and flexible procurement in times of crisis as well as price stability and advantages.”

At FACTUREE, all manufacturing partners are subject to a continuous data-driven, ISO 9001 certified quality management system that checks and ensures the high quality of systems, processes and products. The logistics partners are also checked for reliability before being selected.

Networking at all levels

The Online Manufacturing approach accommodates the needs of manufacturing companies that have to react ever more flexibly to changes in the market – not only in times of crisis. It supports sustainable efficiency gains and is an important component for companies on their way to Industry 4.0. Networking is becoming more prevalent in industry not only in the technical sense – it also applies to the cooperation between various stakeholders. The future of procurement is therefore in platforms and ecosystems.

Read more on “Online Manufacturing – Procurement advantages in series” in the free white paper at: https://www.facturee.de/en/whitepaper-series-production/

Characters: 4,360

Profile of FACTUREE – The Online Manufacturer:

cwmk GmbH, based in Berlin, operates under the brand name FACTUREE as the first Online Manufacturer. The company pursues the goal of enabling its customers to procure modern production parts through digitization, automation and networking. FACTUREE has an extensive production network of over 1000 manufacturing partners from the fields of CNC machining, sheet metal production, 3D printing, casting, forging, and surface technology. More than 15000 machines are constantly available for projects. All partners are subject to a continuous data-driven quality management system certified according to ISO 9001. FACTUREE can realize prototyping projects as well as small and large series production. The customer base is located in the most diverse fields such as mechanical engineering, medical technology, model making, robotics, automotive as well as aerospace. Leading industrial companies like Siemens and Parker Hannifin, SMEs, research institutes and universities are among the customers. FACTUREE is active throughout Europe and has a continuously growing number of customers in other European countries.

Further information: www.facturee.de

Online Manufacturer taps into government funding and helps the long-term unemployed return to the primary labor market

Prime example for reintegration of the long-term unemployed: Federal Labor Minister visited Online Manufacturer FACTUREE

Berlin, 21 November 2022 – Someone who has been unemployed for five years or more is considered difficult to place – the Participation Opportunities Act was passed to change this. Federal Labor Minister Hubertus Heil visited the Online Manufacturer FACTUREE (www.facturee.de) and witnessed firsthand how people can be effectively reintegrated into working life after many years of unemployment. The Berlin-based company uses government funding and very successfully employs five people who were previously unemployed for many years. Having gained a foothold in the primary labor market again, they have already assumed important roles in various divisions of the company. Therefore, after the funding ends, they will be offered permanent positions. Hubertus Heil cited this example in his speech to the Bundestag on 10 November 2022: https://bit.ly/3O59hoe

Getting the long-term unemployed back to work was a great challenge for many years. In this context, the Participation Opportunities Act of the Federal Ministry of Labor and Social Affairs, which has been in force since 1 January 2019 (§ 16i SGB II), is intended to improve the employment opportunities of people on the margins of the labor market and facilitate their social participation. The objective of the model is to motivate employers to fill open positions with long-term unemployed persons. Federal Labor Minister Hubertus Heil learned how this works in practice during talks with staff at FACTUREE who are employed via the Participation Opportunities Act.

Benjamin Schwab, co-founder and CMO of FACTUREE, explains: “We are very pleased that we took this step. The instrument gives people whose careers have been derailed a real chance to enter the labor market again. By effectively integrating people who were chronically unemployed, we would like to encourage other companies to follow our example.”

Social labor market offers prospects – initial skepticism vanished

The goal of the Participation Opportunities Act is to support all parties involved. When a long-term unemployed person is hired, the state pays their full wages in the first two years. Then the state pays 90 percent of their wages in the third year, 80 percent in the fourth year, and 70 percent in the fifth year.

Prior to implementation, there were also skeptics at FACTUREE. Moritz König, CEO of FACTUREE, says: “Initially, I had major concerns when I was approached about this issue. I thought that if someone is unemployed for so long, there must be a reason. But I agreed to go ahead because there is practically no risk for the employer. Looking back, I have to say I was actually mistaken … and I’m very happy about that.”

Benjamin Schwab emphasizes: “The model does not guarantee success. Both sides have to be ‘willing’ for the public program to work – employees who are willing to perform, and employers who are willing to be patient and understanding of the very different backgrounds people bring with them.”

The five female and male long-term unemployed persons working at FACTUREE have different career histories. Andreas, storage logistics employee at FACTUREE, was unemployed for a long time and had already given up hope of ever working again. He says: “Thanks to the Participation Opportunities Act, I have now found work in the primary, regular labor market – not in an association or other organization that operates in the secondary labor market. This was important for me. Now my life is structured and I feel optimally integrated.”

Christian, who was unemployed for 15 years, explains: “The Participation Opportunities Act and my employer’s willingness to take a chance restored my quality of life.”

Employers and taxpayers also benefit

All parties benefit from the Participation Opportunities Act – the long-term unemployed, the employers and also taxpayers. Long-term unemployed people get a real opportunity to return to the primary labor market, while companies receive generous wage subsidies that help create new jobs with little to no risk. Taxpayers also benefit because in the long term, fewer people need government assistance.

Rapid growth through public funding instead of venture capital

One distinguishing feature of FACTUREE is that the company has been fully self-financed since it was founded and thus, unlike the usual practice in the sector, operates without investor funds. Five years after it was founded, the company generates 8-figure sales volumes and annual growth rates around 100 percent. Contributing to this positive business development is the fact that from the start, FACTUREE has used public funding programs such as the Participation Opportunities Act that offers pre-financing of jobs.

FACTUREE plans to offer permanent employment

Benjamin Schwab says: “The model works so well for us that we want to offer permanent jobs to all those concerned even after the end of the funding period – i.e. when we no longer receive wage subsidies from the government. We also encourage other companies to make use of the instruments of the social labor market so that even more people can return to permanent employment. We would like to thank the Federal Ministry of Labor and Hubertus Heil for giving us this platform to share our success story with the public.”

Characters: 3,803

Profile of FACTUREE – The Online Manufacturer:

cwmk GmbH, based in Berlin, operates under the brand name FACTUREE as the first Online Manufacturer. The company pursues the goal of enabling its customers to procure modern production parts through digitization, automation and networking. FACTUREE has an extensive production network of over 1000 manufacturing partners from the fields of CNC machining, sheet metal production, 3D printing, casting, forging, and surface technology. More than 15000 machines are constantly available for projects. All partners are subject to a continuous data-driven quality management system certified according to ISO 9001. FACTUREE can realize prototyping projects as well as small and large series production. The customer base is located in the most diverse fields such as mechanical engineering, medical technology, model making, robotics, automotive as well as aerospace. Leading industrial companies like Siemens and Parker Hannifin, SMEs, research institutes and universities are among the customers. FACTUREE is active throughout Europe and has a continuously growing number of customers in other European countries.

Further information: www.facturee.de

Online Manufacturer makes significant contribution to climate protection and creates jobs in Nakhon Province by purchasing CO2 certificates

Fewer emissions and abundant clean energy: FACTUREE supports biogas project in Thailand

Berlin, 15 September 2022 – In Thailand, the production of manioc starch in biogas plants causes large quantities of wastewater, releasing methane into the atmosphere. The Nakhon biogas project from South Pole, developer of international climate protection projects, reduces the emissions and allows for sustainable generation of electricity from wastewater biogas. Online Manufacturer FACTUREE (www.facturee.de) supports this environmental project and assumes ecological responsibility by buying CO2 certificates. The company thus makes a significant contribution to reducing emissions, treating water, creating jobs and supporting educational activities in Nakhon Province.

Biogas is an important addition to wind and sunlight as renewable energy sources. Formerly, wastewater from biogas plants in Nakhon Province was treated in open lagoons. This process resulted in the constant release of methane and a high level of environmental pollution. A climate project finally made a real difference to the situation.

Emission reduction and generation of clean energy

With the Nakhon biogas project, certified with the recognized Gold Standard (Emission Reduction Project Development Standards (southpole.com)), South Pole has developed and implemented a climate protection strategy involving a closed anaerobic lagoon system installed in Nakhon that captures methane emissions and uses them to generate clean energy.

South Pole develops and implements holistic strategies for reducing emissions. The company’s various projects transform climate protection to long-term business opportunities for companies, governments and organizations throughout the world. In addition to reducing emissions, South Pole projects create social and ecological added value – especially for less privileged societies that are threatened by climate change.

Online Manufacturer FACTUREE, a brand of cwmk GmbH, focusses its activities not only on quality but also on sustainability and climate protection and regularly supports relevant projects – including the Nakhon biogas project.

Benjamin Schwab, co-founder and CMO of FACTUREE, explains: “Biogas plants are an important part of energy transition. But they can also be counterproductive if methane escapes into the atmosphere in an uncontrolled way. The Nakhon biogas project solves this problem, considerably improving the local air and water quality in Thailand. By purchasing CO2 certificates from South Pole, we support these developments.”

Generating large water resources

The Nakhon biogas project prevents the emission of powerful greenhouse gases and significantly reduces the use of fossil fuels. The treated water is used in Nakhon Province to irrigate nearby fields, among other things.

Benjamin Schwab says, “Every year, an average of 850,000 cubic meters of wastewater can be treated in the Nakhon project to become a clean water resource. This also benefits fish farming, boosting the economy in the region. The project thus creates jobs for the local population. Various educational activities and social programs are also supported. The entire endeavor is in line with our understanding of ecological, social and economic responsibility, so we are happy to make our contribution here.”

FACTUREE has voluntarily offset its CO2 emissions by purchasing CO2 certificates since the company came into existence. The Online Manufacturer thus promotes sustainability not only with its progressive business model for modern procurement, but also through values such as consistency, environmental awareness and social commitment.

Characters: 3,803

Profile of FACTUREE – The Online Manufacturer:

cwmk GmbH, based in Berlin, operates under the brand name FACTUREE as the first Online Manufacturer. The company pursues the goal of enabling its customers to procure modern production parts through digitization, automation and networking. FACTUREE has an extensive production network of over 1000 manufacturing partners from the fields of CNC machining, sheet metal production, 3D printing, casting, forging, and surface technology. More than 15000 machines are constantly available for projects. All partners are subject to a continuous data-driven quality management system certified according to ISO 9001. FACTUREE can realize prototyping projects as well as small and large series production. The customer base is located in the most diverse fields such as mechanical engineering, medical technology, model making, robotics, automotive as well as aerospace. Leading industrial companies like Siemens and Parker Hannifin, SMEs, research institutes and universities are among the customers. FACTUREE is active throughout Europe and has a continuously growing number of customers in other European countries.

Further information: www.facturee.de

Online Manufacturer supplies components for attaching batteries to e-mountain bikes of a global bicycle manufacturer

Components from FACTUREE get into gear with GHOST-Bikes

Berlin, 8 August 2022 – The world has seen a real boom in bicycles since the coronavirus pandemic – and those with gears are booming in particular. However, e-bikes require a complex design with a high level of precision. For an e-bike line of bicycle manufacturer GHOST-Bikes, the Online Manufacturer FACTUREE (www.facturee.de) supplies three key components in serial production. The parts are used to attach and stabilize the battery on the frame of the bicycle. The manufactured components also enable GHOST-Bikes to develop and implement functional technical solutions for prototyping within a very short time.

GHOST-Bikes was founded more than 25 years ago in Waldsassen, Germany, and has become a global company, producing over 150,000 bicycles annually. In addition to gravel and mountain bikes, its portfolio also includes mountain, city and trekking e-bikes.

According to GHOST-Bikes GmbH, the complexity of the products in this field is steadily increasing, in particular due to the boom in the electric bicycle sector. At the same time, demand is increasing. GHOST-Bikes has therefore always looked for optimized manufacturing methods that are more efficient and cost-effective while maintaining very high quality. As a result of this, the company commissioned FACTUREE with the Online Manufacturing of various milled and turned parts, bent sheet metal parts, and individual parts in serial production, for example for their E-RIOT e-mountain bikes. The components are also used to support prototyping.